ALUMINUM FOIL CONTAINER MANUFACTURING: A COMPREHENSIVE PROCESS OVERVIEW

(Introduction Title) From Ingot to Essential: The Engineering Behind Everyday Packaging

In the vast ecosystem of global logistics and food service, the humble aluminum foil container stands as a testament to manufacturing ingenuity. Often perceived as a simple disposable item, its creation is, in reality, a complex symphony of material science, mechanical engineering, and rigorous quality control. The journey from a massive aluminum coil to the precisely formed, reliable container that protects, preserves, and presents our food is a sophisticated industrial process. It demands substantial capital investment, deep technical expertise, and an unwavering commitment to operational excellence.

This document is not a simple explainer. It is a comprehensive technical and operational breakdown. ✍️ Authored from the perspective of an industrial process engineer, this analysis deconstructs the entire manufacturing value chain. We will establish the critical parameters for raw material selection. We will meticulously walk through the mechanics of the high-speed stamping process. We will implement a Total Quality Management framework essential for food-grade production. Finally, we will explore the operational strategies that separate market leaders from mere producers. This overview is engineered for investors, production managers, engineers, and business leaders seeking a granular understanding of what it takes to manufacture this essential commodity at scale and to the highest standards of quality and safety.

TABLE OF CONTENTS

Foundational Pillars: Raw Material Science and Production Strategy

The Mechanical Core: The Precision Stamping and Forming Process

Quality Assurance: A Non-Negotiable Framework for Manufacturing Excellence

Innovation in Formation: Diversification and Advanced Product Design

Operational Integrity: Plant Management, Safety, and Sustainability

1. Foundational Pillars: Raw Material Science and Production Strategy

The entire manufacturing process hinges on two foundational elements: the quality of the raw material and the strategic framework governing the production line. A flaw in the initial material or a weak operational strategy will inevitably cascade into defects, inefficiency, and financial loss.

Defining the strategic importance of certified raw materials

The Case: "AluForm Precision Manufacturing," a startup in the food packaging sector.

The Problem (The "Before"): To minimize initial costs, AluForm sourced aluminum coils from a non-certified, low-cost international supplier. The material had inconsistent thickness and alloy composition. This resulted in frequent web breaks in the press line, inconsistent container wall strength, and a high scrap rate of over 15%. Finished products often showed "pinhole" defects, compromising food safety.

The Solution (The "After"): Management pivoted to a strategic sourcing model, partnering with a certified supplier of food-grade aluminum alloys (like 3003 or 8011 series). This supplier provided a Certificate of Analysis (COA) with every batch, guaranteeing alloy purity and thickness tolerance.

The Result: The scrap rate plummeted to under 2%. Press line uptime increased by 30% due to the elimination of web breaks. The finished products consistently met and exceeded quality standards, allowing AluForm to secure contracts with major food service distributors. This illustrates that raw material is not a cost center, but an investment in production stability and market reputation.

Key strategic considerations for establishing a production line

Strength - High Demand: The global demand for disposable, hygienic, and recyclable food packaging is consistently strong and growing, providing a stable market.

Weakness - High Capital Expenditure: The initial investment in high-tonnage pneumatic presses, precision tooling (dies), and automated conveyor systems is substantial.

Opportunity - Niche Specialization: Opportunity exists to specialize in high-margin products like smoothwall containers, colored/lacquered trays, or multi-compartment meal-prep containers, which command premium pricing.

Threat - Material Price Volatility: The price of aluminum is a global commodity, subject to market fluctuations. A sudden price surge can significantly impact profit margins if not managed through strategic hedging or long-term contracts.

Caption: A strategic approach to raw material sourcing is the bedrock of efficient and reliable manufacturing.

ALT Text: A diagram showing the strategic importance of raw materials in aluminum foil container manufacturing.

2. The Mechanical Core: The Precision Stamping and Forming Process

This is the heart of the operation where raw material is transformed into a finished product. It is a process of immense force and minute precision, executed at incredible speeds. Understanding these mechanics is crucial to appreciating the entire production cycle.

Mandatory machinery and tooling specifications

Name: H-Frame Pneumatic Press - Core Specification Sheet (PSS-M01)

Icon: 📋

Content:

Tonnage Capacity: The press MUST have an adequate force rating (typically 45T to 125T) to cleanly cut and form the aluminum sheet without tearing. Tonnage determines the maximum size and complexity of the container that can be produced.

Stroke Speed (Strokes Per Minute - SPM): High-speed production presses operate between 40-70 SPM. The speed must be adjustable to accommodate different container depths and material thicknesses.

Tooling (Die Set): This is the most critical component. It consists of the cutting punch, forming punch, and cavity. It MUST be crafted from high-durability tool steel (e.g., D2, SKD11) and machined to tolerances within micrometers to ensure consistent container shape, curl rim quality, and a long operational life.

Automated Feed System: A pneumatic or electronic feeder is essential for pulling the aluminum web from the decoiler into the press at a precise, synchronized rate.

The step-by-step mechanical transformation protocol

Step 1: Decoiling. A large, heavy coil of aluminum (often weighing over a ton) is mounted on an automated uncoiler. This machine carefully unwinds the sheet of foil.

Step 2: Lubrication. The flat aluminum web passes through a lubrication unit, which applies a micro-thin layer of food-grade lubricating oil. This is critical to reduce friction during the forming process, prevent tearing, and extend the life of the tooling.

Step 3: Feeding. The lubricated web is pulled into the press by the automated feeder, which positions the exact required length of material under the die for each stroke.

Step 4: Stamping (The Stroke). In a single, powerful, high-speed action, the press ram descends. The die set simultaneously cuts the blank shape and deep-draws it into the final container form.

Step 5: Ejection & Scrap Management. As the ram ascends, a blast of compressed air ejects the newly formed container from the die onto a conveyor belt. The remaining web of material (the "scrap skeleton") is simultaneously chopped or re-coiled for collection and recycling.

3. Quality Assurance: A Non-Negotiable Framework for Manufacturing Excellence

In food-grade manufacturing, quality assurance is not a final step; it is a pervasive philosophy embedded in every stage of the process. A single quality failure can lead to product recalls, loss of major contracts, and irreparable brand damage.

Deconstructing the Total Quality Management (TQM) framework

Central Theme: The Zero-Defect Manufacturing Mandate

Branch 1: Inbound Material Control (IMC)

COA Verification: Cross-referencing the supplier's Certificate of Analysis with every batch received.

Physical Inspection: Measuring coil thickness with a micrometer and checking for surface defects or blemishes before it enters the line.

Branch 2: In-Process Quality Control (IPQC)

First-Off Inspection: The first 5-10 containers from every new coil or tool setup are subjected to intense scrutiny for dimensions, form, and defects.

Automated Vision Systems: Cameras installed on the line to detect common defects like pinholes, cracks, or incomplete rim curls in real-time.

Hourly Operator Checks: Production line operators perform manual checks on samples every hour to monitor for tooling wear or press misalignment.

Branch 3: Finished Goods Validation (FGV)

Load Bearing Test: Random samples are filled with a standard weight to test structural integrity.

Liquid Containment Test: Containers are filled with dyed water and placed on white paper to test for leaks over a set period.

Stacking & Packaging Check: Ensuring containers stack uniformly without jamming and fit correctly into their final packaging (sleeves/cartons).

How a robust QA system delivers exponential ROI

Scenario A - Reactive "End-of-Line" Inspection:

A manufacturer relies only on a final check before boxing. A die alignment issue goes unnoticed for an hour, producing 3,000 defective containers with a slightly malformed rim. This batch is shipped. A major client's automated lidding machine jams repeatedly, causing a production halt at their facility. The entire shipment is rejected, resulting in a total loss, freight costs for the return, and a severe penalty clause being activated. The long-term cost of reputational damage is immeasurable.

Scenario B - Proactive "In-Process" QA System:

A manufacturer invests in a robust TQM system. An hourly operator check detects a minor deviation in the container's rim curl. The line is paused for 5 minutes for a micro-adjustment to the die. A total of only 50-60 containers are flagged as scrap. Production resumes, and the client receives a shipment of 100% compliant products. The slightly higher operational cost of the TQM system prevents a catastrophic financial and reputational failure, delivering an immense ROI.

Caption: Rigorous, multi-stage quality control is not an expense, but a crucial investment in product integrity and client trust.

ALT Text: A chart showing the total quality management framework in aluminum container production.

4. Innovation in Formation: Diversification and Advanced Product Design

Thriving in the modern packaging market requires moving beyond the standard silver rectangle. True market leadership is achieved through continuous innovation in container design, functionality, and aesthetics to meet evolving consumer and commercial demands.

Integrating product innovation through advanced tooling and materials

Phase 1 (The Utility Era): Early production focused solely on basic, functional containers—primarily round or rectangular pans. The singular goal was containment. Tooling was simple, and efficiency was the only metric.

Phase 2 (The Convenience Era): Market demand shifted towards convenience. This led to the development of multi-compartment tooling for "TV dinner" style meals. This required more complex, multi-cavity dies and a greater level of precision in the stamping process.

Phase 3 (The Premiumization Era): The current market demands a more premium experience. This has driven the evolution towards:

Smoothwall Containers: These have a sleek, wrinkle-free appearance and can be hermetically sealed with film, making them ideal for high-end ready meals. They require a different drawing process and highly polished tooling.

Lacquered/Colored Containers: Applying food-safe lacquers (in colors like black, gold, or white) to the aluminum coil before stamping allows for branded, aesthetically pleasing packaging that enhances product presentation on retail shelves.

Leveraging modular design for a diverse product portfolio

The "Flexible Tooling Platform" Module:

Components: (1) A universal die-set base that fits into the press + (2) Interchangeable modular inserts for different container shapes and sizes + (3) A range of colored and treated aluminum coils.

Application: A manufacturer can use this system to rapidly switch production.

Morning Shift: Run a standard "Half-Size Deep" pan using the #101 insert and standard 8011 alloy coil.

Afternoon Shift: In under an hour, swap to the #205 insert to produce a two-compartment black lacquered container for a gourmet food client.

This modular approach dramatically increases a plant's flexibility, allowing it to serve a wider range of market segments without investing in entirely separate production lines for each product.

5. Operational Integrity: Plant Management, Safety, and Sustainability

A manufacturing plant's long-term success is not just determined by its output, but by the integrity of its day-to-day operations. This includes rigorous machine maintenance, an uncompromising safety culture, and responsible environmental practices.

Vetting maintenance strategies for maximum uptime

Argument A (The "Run-to-Failure" Mentality): "We can't afford to stop the press for scheduled maintenance this week. We have a major order to fill. We'll fix it if something breaks. We need to maximize short-term output."

Argument B (The "Preventive Maintenance" Strategy): "Stopping the press for a scheduled 4-hour preventive maintenance (PM) session is a strategic necessity. During that time, we will lubricate key bearings, inspect the pneumatic lines, and sharpen the cutting die. This planned downtime prevents an unplanned, catastrophic 3-day failure of a main crankshaft next month. A minor, controlled loss of production now prevents a major, uncontrolled loss later. Uptime is not about running non-stop; it's about running reliably." A professional plant manager always prioritizes long-term asset reliability over short-term production numbers.

The environmental and operational life-cycle of aluminum

1. Scrap Collection: The "scrap skeleton" left after stamping is the most valuable by-product. It is collected via automated conveyor systems and compressed into dense, manageable bales. This scrap is pure, high-quality aluminum.

2. Closed-Loop Recycling: These bales are sold directly back to aluminum mills. Because the alloy is known and uncontaminated, it can be re-melted and re-cast into new aluminum coils with minimal energy input.

3. Energy Savings: Recycling aluminum uses approximately 95% less energy than producing primary aluminum from bauxite ore. This creates a massive environmental benefit and a significant cost efficiency within the supply chain.

4. Market Positioning: A manufacturer that can verifiably demonstrate a closed-loop recycling program for 100% of its production scrap can position itself as a sustainable partner, which is a powerful differentiator for environmentally conscious clients.

Caption: Operational excellence is a fusion of preventive maintenance, stringent safety protocols, and a commitment to sustainability.

ALT Text: A depiction of the safe and efficient operational management within an aluminum foil container factory.

(Conclusion Title) The Aluminum Foil Container: An Engineered Keystone of the Global Supply Chain

This in-depth analysis has navigated the intricate path of aluminum foil container manufacturing, from the elemental properties of its raw material to the complex dance of high-speed industrial machinery. The evidence is irrefutable: creating this ubiquitous product is a capital-intensive, technically demanding endeavor. It is a business where precision is measured in microns and success is dictated by a relentless dedication to quality and efficiency.

The superiority of a well-made container in terms of safety, performance, and reliability is not an accident; it is the direct result of strategic material sourcing, investment in precision engineering, and the implementation of a comprehensive quality culture. For industry stakeholders, understanding this process is fundamental. It reveals that the simple aluminum tray is not just a piece of packaging, but an engineered asset—a critical enabler of the modern food service and logistics industries, safeguarding product integrity from the production line to the end consumer. 🏆⚙️

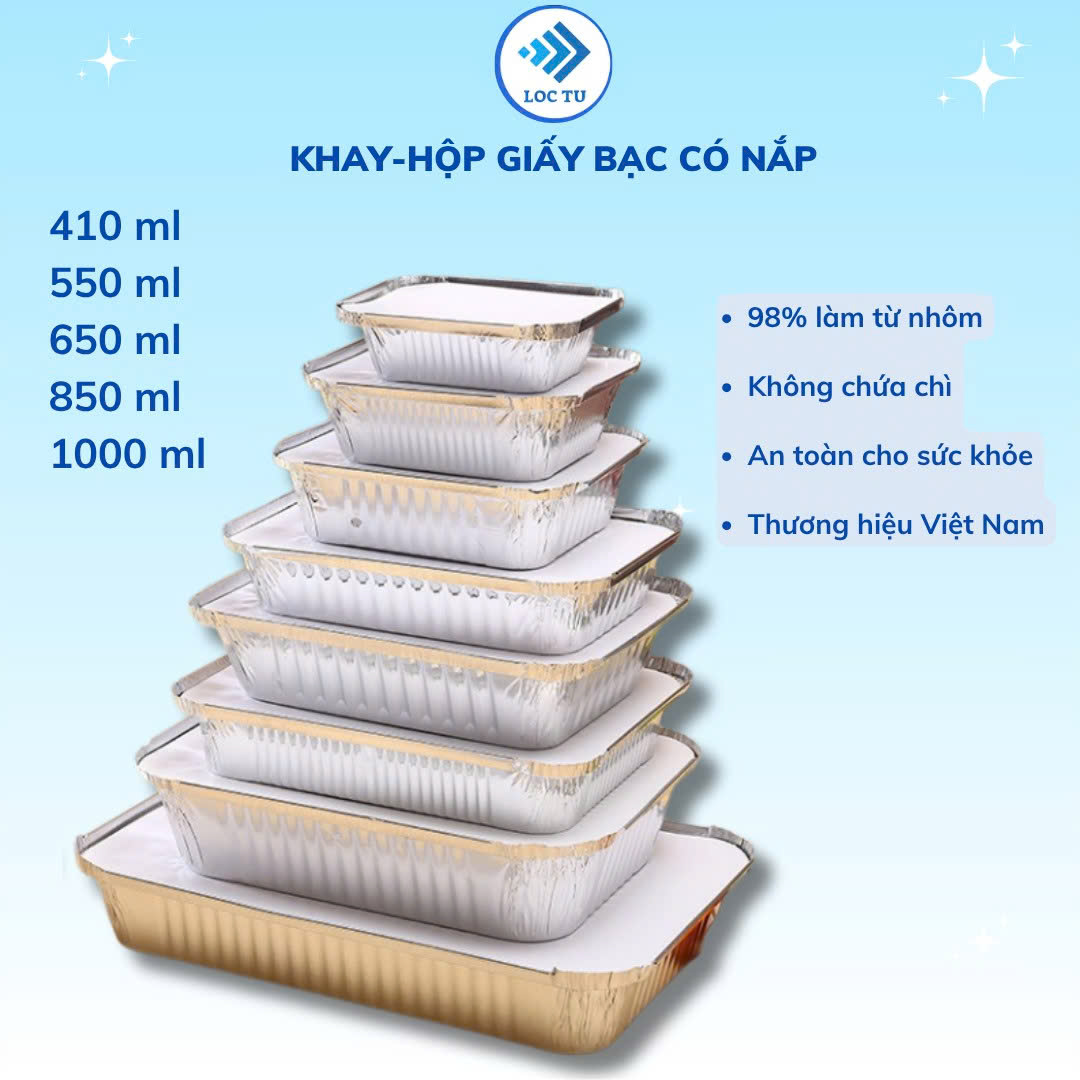

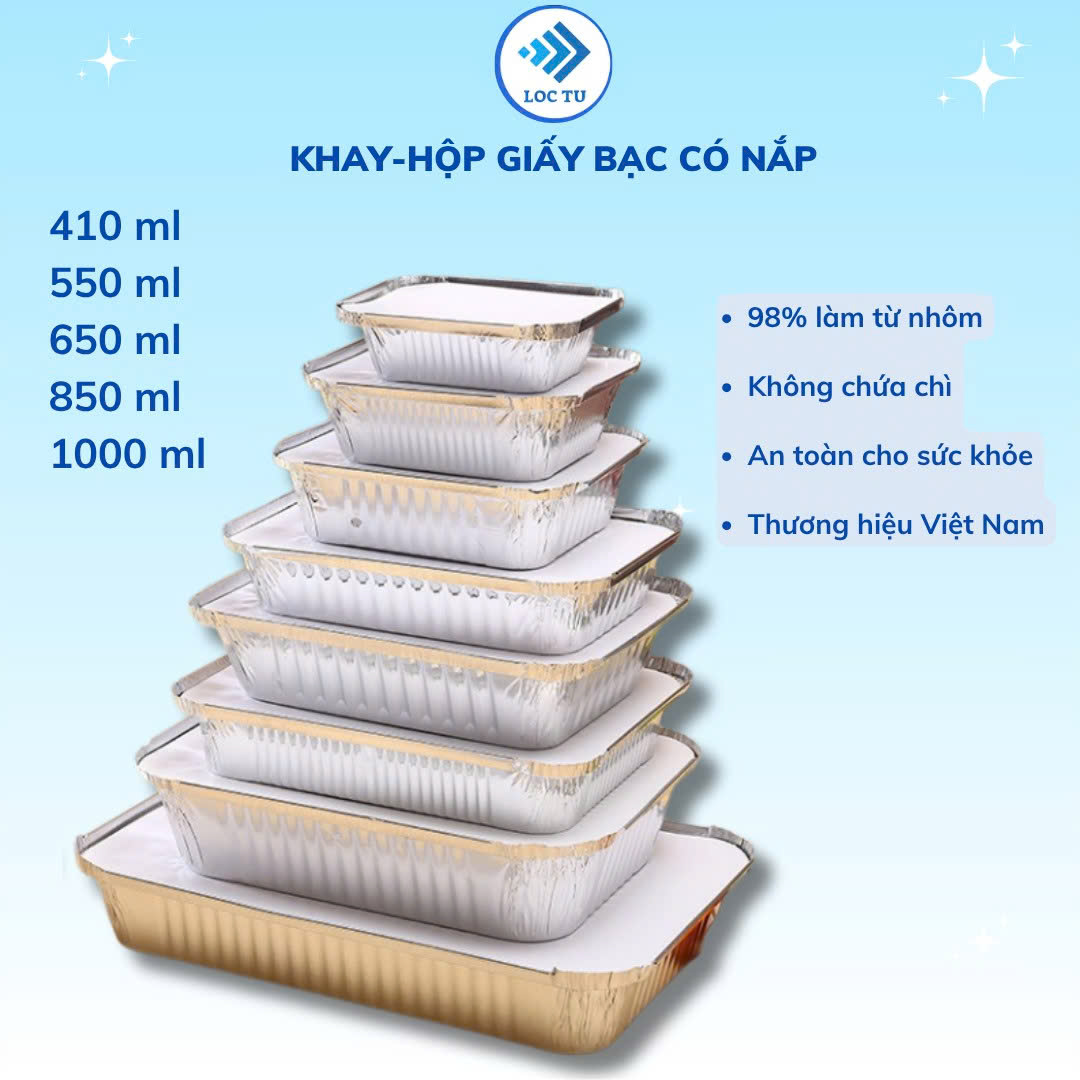

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

At the forefront of the food packaging industry, Loc Tu Manufacturing & Trading Co., Ltd. stands as a premier manufacturer and supplier of high-quality aluminum trays and foil rolls. We are dedicated to providing innovative, safe, and reliable packaging solutions tailored to the dynamic needs of the modern food landscape. Our foundation is b0uilt upon state-of-the-art manufacturing facilities, equipped with advanced production lines engineered for precision and efficiency. This technological edge allows Loc Tu to consistently deliver aluminum trays and foil rolls that not only meet but exceed rigorous international food safety standards.

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

Loc Tu Manufacturing & Trading Co., Ltd. is more than just a supplier; we are your strategic partner in delivering high-caliber aluminum food packaging solutions. Specializing in a comprehensive range of aluminum trays, versatile foil rolls, and convenient disposable food containers.

We serve a diverse clientele – from individual households and local food vendors to large-scale restaurants, catering companies, and prestigious hotel chains. Our unwavering dedication to safety, sustainability, innovation, and customer satisfaction makes us the trusted choice for businesses and consumers seeking reliable, high-performance packaging.

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀