ALUMINUM FOIL FOOD PACKAGING: A WHITE PAPER ON A SUPERIOR ADVANCED

ALUMINUM FOIL FOOD PACKAGING: A WHITE PAPER ON A SUPERIOR ADVANCED PACKAGING MATERIAL

Table of Contents

Introduction to Aluminum Foil Food Packaging

The Fundamental Properties of Aluminum Foil Food Packaging

Advanced Barrier Functions of Aluminum Foil Food Packaging

Thermal Management and Versatility in Aluminum Foil Food Packaging

Safety and Regulatory Compliance in Aluminum Foil Food Packaging

Sustainability and Recycling in Aluminum Foil Food Packaging

Innovations and Future Trends in Aluminum Foil Food Packaging

Conclusion: The Superiority of Aluminum Foil Food Packaging

1. Introduction to Aluminum Foil Food Packaging

In the dynamic landscape of food preservation and distribution, the choice of packaging material is paramount. It dictates shelf life, preserves nutritional value, ensures safety, and influences consumer perception. Among the myriad of available options, aluminum foil food packaging stands out as a consistently superior and advanced solution. This white paper aims to delve into the intrinsic properties that make aluminum foil an indispensable material for safeguarding food products, exploring its unparalleled barrier capabilities, thermal versatility, safety aspects, and its increasingly important role in sustainable packaging solutions.

Evolution of Food Packaging: From early natural containers to sophisticated multi-layered structures, food packaging has evolved to meet complex demands for hygiene, preservation, and convenience.

The Role of Advanced Materials: Modern food supply chains necessitate materials that can withstand diverse environmental conditions, protect against spoilage, and maintain product quality from farm to fork.

Why Aluminum Foil? Aluminum foil's unique combination of properties makes it exceptionally well-suited for a wide range of food packaging applications, addressing critical needs that other materials often struggle to fulfill comprehensively. Its thin, metallic nature offers a distinct advantage over plastics, papers, and glass in specific scenarios.

Aluminumn foil

2. The Fundamental Properties of Aluminum Foil Food Packaging

The remarkable performance of aluminum foil food packaging stems from the inherent characteristics of aluminum itself, meticulously engineered into thin, flexible sheets. These fundamental properties form the bedrock of its effectiveness as a high-performance packaging material.

Exceptional Barrier Performance:

Impermeability to Gases: Aluminum foil is virtually impermeable to oxygen, nitrogen, and carbon dioxide. This is critical for preventing oxidative spoilage, maintaining product freshness, and extending shelf life, particularly for oxygen-sensitive foods like snacks, coffee, and processed meats.

Impermeability to Moisture: It acts as an absolute barrier to water vapor, preventing moisture ingress (which can lead to sogginess or microbial growth) and moisture egress (which can cause dehydration or freezer burn). This property is invaluable for maintaining the texture and quality of dry goods, frozen foods, and bakery items.

Light Blocking: Being opaque, aluminum foil completely blocks out light, including ultraviolet (UV) radiation. Light can degrade vitamins, fats, and colors in food, leading to nutrient loss and off-flavors. Foil protects light-sensitive products, such as dairy, chocolate, and certain oils.

Aroma and Flavor Preservation: Its impermeable nature means that food odors cannot escape, nor can external odors penetrate the package. This preserves the intrinsic aroma and flavor of the food product, preventing cross-contamination of scents.

Thermal Conductivity and Reflectivity:

Excellent Heat Conductor: Aluminum is an outstanding conductor of heat, allowing for rapid and even heat transfer during cooking, baking, or chilling processes. This ensures uniform cooking and efficient temperature management.

High Thermal Reflectivity: Foil reflects radiant heat effectively, making it ideal for insulation. It can keep hot foods hot and cold foods cold, crucial for food delivery, catering, and oven-to-table applications.

Formability and Dead-Fold Characteristics:

Malleability: Aluminum foil is highly ductile and malleable, meaning it can be easily formed into various shapes without breaking. This allows for intricate package designs and tight seals.

Dead-Fold: Once folded or creased, aluminum foil retains its shape. This "dead-fold" characteristic ensures secure seals and wraps that stay in place, preventing product leakage or exposure.

Non-Toxicity and Hygiene:

Food-Grade Purity: Aluminum foil food packaging is produced from high-purity aluminum alloys and manufactured under strict hygienic conditions. It is non-toxic and does not impart flavor or odor to food products.

Sterilization Compatibility: Foil can withstand high temperatures, making it suitable for retort packaging, sterilization, and pasteurization processes without degrading or releasing harmful substances.

3 Main Properties Of Aluminum Foil

3. Advanced Barrier Functions of Aluminum Foil Food Packaging

While the fundamental barrier properties are well-understood, the advanced application and engineering of aluminum foil food packaging enhance these functions, providing superior protection tailored to diverse food product needs.

Protection Against Oxidation:

Oxygen ingress is a primary cause of spoilage, leading to rancidity in fats, color changes in meats, and vitamin degradation. The near-zero oxygen transmission rate (OTR) of aluminum foil virtually eliminates this threat, preserving freshness and nutritional integrity.

This is especially critical for products like nuts, coffee, and snack foods where oxidative spoilage can rapidly compromise quality.

Moisture Management for Optimal Texture:

For dry goods, protection against moisture absorption is key to maintaining crispness and preventing clumping. For moist goods, retaining moisture is vital for texture and palatability. Foil's absolute barrier function performs both roles effectively.

In frozen foods, it prevents freezer burn—a condition caused by dehydration and oxidation that compromises texture and flavor—by preventing water vapor from escaping the product.

Light Degradation Prevention:

Photosensitive vitamins (e.g., Vitamin C, Riboflavin) and fats can be significantly degraded by light exposure. The opacity of aluminum foil provides complete light protection, safeguarding nutrient content and preventing photo-oxidation, which can lead to off-flavors.

This is particularly important for dairy products, oils, and certain pharmaceuticals or nutraceuticals packaged in foil.

Microbial and Pest Exclusion:

The tight seals and impermeable nature of aluminum foil food packaging create a physical barrier that prevents the entry of microorganisms (bacteria, molds, yeasts) and pests. This contributes significantly to extending shelf life and ensuring food safety.

In combination with heat treatments (like retort processing), foil can create commercially sterile environments, allowing for shelf-stable products without refrigeration.

Odor and Flavor Containment/Exclusion:

Foil's impermeability prevents volatile flavor compounds from escaping the package, ensuring the product retains its intended taste and aroma.

Conversely, it prevents undesirable external odors from penetrating the package, protecting the food from tainting during storage or transport. This is highly beneficial in mixed storage environments.

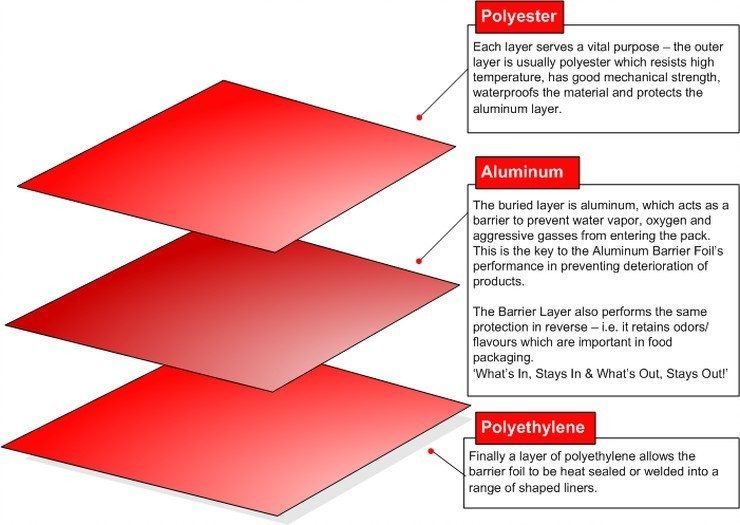

Aluminum Barrier Foil comprises of 3 to 4 layers of different materials

4. Thermal Management and Versatility in Aluminum Foil Food Packaging

Beyond its formidable barrier properties, the thermal characteristics and adaptability of aluminum foil food packaging offer immense versatility, catering to a wide array of processing, cooking, and consumption methods.

High-Temperature Resistance:

Aluminum foil can withstand extreme temperatures encountered during baking, roasting, grilling, and deep-freezing without melting, deforming, or losing its barrier integrity. This makes it suitable for "oven-to-table" packaging solutions.

It is a preferred material for retort pouches and containers, which undergo high-temperature, high-pressure sterilization, creating shelf-stable food products like ready meals, pet food, and soups.

Rapid Heating and Cooling:

Its excellent thermal conductivity facilitates efficient heat transfer, allowing food to heat up or cool down quickly and uniformly. This is advantageous in processes requiring precise temperature control and for rapid chilling of products.

Heat Reflectivity for Insulation:

The shiny surface of aluminum foil reflects up to 98% of radiant heat. This property is exploited in insulated packaging (e.g., thermal bags, insulated liners) to maintain the temperature of hot or cold food during transport or display.

It helps keep frozen products stable during transit and minimizes energy consumption in refrigeration.

Formability and Adaptability for Various Formats:

Pouches and Bags: Used for snacks, sauces, powdered mixes, and retort-sterilized meals.

Lids and Seals: Commonly found on yogurt cups, ready meals, and coffee pods, providing an easy-peel, secure seal.

Trays and Containers: For bake-in-the-oven or grill-ready meals, desserts, and catering packs.

Wraps and Foils: For household use, catering, and deli applications, offering flexible protection.

Blister Packs: For individual portion control and product integrity in confectionery and processed cheese.

Compatibility with Packaging Machinery:

Aluminum foil is easily laminated with other materials (e.g., plastics, paper) to create multi-layer structures that combine the best properties of each material.

It runs efficiently on high-speed packaging lines, allowing for cost-effective and rapid production.

5. Safety and Regulatory Compliance in Aluminum Foil Food Packaging

The safety of any food contact material is non-negotiable. Aluminum foil food packaging is subject to stringent regulations and standards worldwide to ensure it poses no health risks to consumers.

Global Regulatory Acceptance:

Aluminum foil is widely accepted as a safe food contact material by major regulatory bodies such as the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and other national food safety agencies.

These bodies conduct extensive risk assessments based on scientific data to establish safe limits for migration of substances from packaging to food.

Low Migration Rates:

Studies consistently show that the migration of aluminum ions from foil into food, even under conditions of prolonged contact or high temperatures, is extremely low.

The amounts are typically well below the Tolerable Weekly Intake (TWI) established by health organizations, meaning the human body can effectively excrete these trace amounts without accumulation or adverse effects.

Considerations with Acidic/Salty Foods:

While generally safe, prolonged contact (e.g., long-term storage, or high-temperature cooking for hours) with highly acidic or highly salty foods (like tomatoes, citrus fruits, vinegars, heavily salted meats) can slightly increase aluminum migration.

For such specific applications, alternatives or careful monitoring of contact time may be advised, though the overall risk remains very low for typical usage.

No Interaction with Food Quality:

Aluminum foil food packaging is chemically stable and inert, meaning it does not react with food components, alter flavor, or impart off-odors. This ensures the sensory quality of the food product remains intact.

Hygienic Production:

Manufacturers adhere to Good Manufacturing Practices (GMPs) to ensure the purity and cleanliness of the foil during production, minimizing the risk of any contaminants.

Aluminumn foil in Food Safety

6. Sustainability and Recycling in Aluminum Foil Food Packaging

In an era of increasing environmental consciousness, the sustainability profile of packaging materials is critically evaluated. Aluminum foil food packaging offers significant advantages in this regard, particularly due to its high recyclability.

Infinitely Recyclable Material:

Aluminum is a truly circular material. It can be recycled repeatedly without any loss of quality or properties. This means that a piece of aluminum foil can be re-melted and reformed into new aluminum products indefinitely.

Recycling aluminum requires significantly less energy (up to 95% less) compared to producing primary aluminum from bauxite ore, resulting in substantial reductions in greenhouse gas emissions and resource consumption.

Economic Value of Scrap:

Aluminum scrap holds significant economic value, incentivizing collection and recycling efforts. This helps to create a robust recycling infrastructure.

Resource Efficiency:

Despite its protective power, aluminum foil can be manufactured to be incredibly thin and lightweight, minimizing the amount of material required per package and reducing transport costs and carbon footprint.

Role in Reducing Food Waste:

By extending shelf life and protecting food from spoilage, aluminum foil food packaging plays a crucial role in preventing food waste, which is a major contributor to environmental impact. Reduced food waste translates to lower resource consumption (water, energy, land) associated with food production.

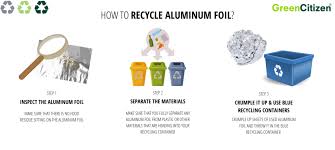

Challenges in Recycling:

Contamination: Food residue can sometimes contaminate foil, making recycling more challenging if not properly cleaned.

Laminated Structures: When aluminum foil is part of a multi-layer laminate with plastics or paper, separating the materials for recycling can be complex. However, technological advancements in recycling are addressing these challenges (e.g., delamination processes).

Consumer Education: Public awareness and proper sorting at the household level are vital for increasing aluminum foil recycling rates. Initiatives are ongoing to educate consumers on how to prepare foil for recycling (e.g., cleaning and balling it up).

Life Cycle Assessment (LCA):

Comprehensive LCAs often demonstrate that aluminum foil, despite being energy-intensive to produce initially, has a favorable environmental profile when its protective qualities (reducing food waste) and high recyclability are factored in.

Recycling methods for Aluminumn Foil

7. Innovations and Future Trends in Aluminum Foil Food Packaging

The field of aluminum foil food packaging is not static; ongoing research and development are pushing the boundaries of its capabilities, aiming for enhanced performance, greater sustainability, and new functionalities.

Thinner Gauges with Enhanced Strength:

Advances in metallurgy and rolling technology allow for the production of thinner foils that maintain or even improve strength and barrier properties. This reduces material usage and packaging weight.

Advanced Coatings and Laminates:

Development of new, high-performance coatings and specialized laminates that offer improved adhesion, enhanced barrier properties, anti-corrosion features, or specific functionalities (e.g., anti-fog, easy-peel).

Research into bio-based coatings aims to combine sustainability with barrier performance.

Smart and Active Packaging Integration:

Integration of sensors within foil packaging that can monitor food freshness, temperature fluctuations, or detect spoilage.

Development of active packaging systems where foil layers can incorporate oxygen scavengers, moisture absorbers, or antimicrobial agents to actively extend shelf life and enhance food safety.

Improved Recyclability of Laminates:

Focus on developing laminated structures that are easier to separate and recycle, or creating monomaterial alternatives where aluminum foil can be effectively recovered from mixed waste streams.

Innovation in delamination technologies to efficiently separate foil from other layers in multi-material packaging.

Consumer Convenience Features:

Development of easy-open/re-sealable features on foil packaging to enhance consumer convenience and help preserve leftovers.

New printing technologies that allow for vibrant, high-quality graphics directly on foil, improving brand appeal.

Sustainable Sourcing:

Increasing use of recycled content in the production of aluminum foil and sourcing from suppliers committed to responsible and ethical aluminum production.

3 main properties of Aluminumn Foil

8. Conclusion: The Superiority of Aluminum Foil Food Packaging

In conclusion, aluminum foil food packaging stands as a testament to advanced material science, offering an unparalleled combination of properties that make it a superior choice for safeguarding food products. Its absolute barrier to gases, moisture, and light, coupled with its remarkable thermal management capabilities and non-toxic nature, ensures optimal preservation of freshness, nutritional value, and sensory quality.

Beyond its technical prowess, aluminum foil's inherent recyclability and its significant contribution to reducing food waste underscore its role as a responsible and increasingly sustainable packaging material. As innovations continue to push the boundaries of its performance and environmental footprint, aluminum foil food packaging remains at the forefront of advanced packaging solutions, providing both industry and consumers with a reliable, versatile, and eco-conscious option for ensuring food safety and quality in a complex global supply chain. Its continued evolution solidifies its position as a truly advanced and superior packaging material, critical for the future of food preservation.

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why Choose Loc Tu:

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Website: ALUMINUMFOILVN

📌 HOTLINE/ZALO: +84.969.787.309

📌 Facebook: Khay nhom thuc pham

📌 Youtube: Khay nhom thuc pham Loc Tu

📌 Tik Tok: Khay nhom Loc Tu

📌 Shopee: Khay nhom thuc pham Loc Tu

📌 Telegram: Khay Nhom Thuc Pham Loc Tu

📌 Whatsapp: +84.969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays, foil, and food packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]