ALUMINUM FOIL FOR SEAFOOD: A CULINARY AND TECHNICAL COMPENDIUM

ALUMINUM FOIL FOR SEAFOOD: A CULINARY AND TECHNICAL COMPENDIUM FOR THE MODERN CHEF

(Introduction Title) Beyond a Kitchen Staple: Foil as a Culinary Instrument

TABLE OF CONTENTS

The Foundational Science: Why Aluminum Foil is a Superior Medium for Seafood Technical Specifications: A Non-Negotiable Framework for Culinary Foil Mastering the Method: Core Culinary Techniques for Foil-Cooked Seafood Advanced Gastronomy: The Art of Flavor Infusion and Texture Control Operational Excellence: Best Practices and Pitfall Avoidance in the Kitchen

1. The Foundational Science: Why Aluminum Foil is a Superior Medium for Seafood

Defining the scientific role of aluminum foil in seafood cookery

The Case: "The Gilded Dolphin," a fine-dining establishment known for its signature "Whole Roasted Branzino with Mediterranean Aromatics."The Problem (The "Before"): The chefs initially used open-pan roasting. This often resulted in inconsistent cooking—the thinner tail section would overcook and dry out before the thicker body was cooked through. The delicate aromatic oils from lemon and herbs would volatilize and dissipate in the high heat of the oven, resulting in a muted flavor profile.The Solution (The "After"): The Executive Chef implemented a technique using a heavy-duty foil pouch (a method known asen papillote ). The branzino was seasoned and enclosed in the foil with herbs, sliced citrus, and a splash of white wine before being placed in the oven.The Result: The sealed foil pouch trapped steam, creating a convection effect that cooked the fish incredibly evenly from all sides. The moisture was locked in, resulting in a supremely tender and succulent texture. Crucially, all the volatile aromatic compounds were contained within the pouch, infusing deeply into the fish's flesh. This demonstrates how foil transforms a cooking process from a basic application of heat to a controlled, flavor-infusing science.

The core advantages of the foil-seafood matrix

Strength - Moisture Retention: Aluminum foil is impermeable. When sealed, it creates a vapor-tight barrier, trapping the seafood's natural moisture and any added liquids. This prevents dehydration, which is the primary challenge in cooking lean fish, resulting in an exceptionally tender and flaky texture.Strength - Uniform Heat Conduction: Aluminum is an excellent thermal conductor. It distributes heat evenly across the entire surface of the seafood. This eliminates "hot spots" common in direct-heat methods, ensuring the protein cooks through uniformly without overcooking certain areas.Opportunity - Aromatic Infusion: The sealed environment is a perfect vessel for flavor infusion. Aromatic ingredients like herbs, citrus, garlic, and spices release their volatile compounds, which are then trapped and forced to permeate the flesh of the seafood. This creates a much deeper and more complex flavor profile than surface-level seasoning.Threat - Absence of Maillard Reaction: The high-moisture, steaming environment inside a foil packet prevents the Maillard reaction and caramelization, which are responsible for the browning and deep savory flavors found in grilling or searing. This must be a deliberate choice for a moist-heat cooking method.

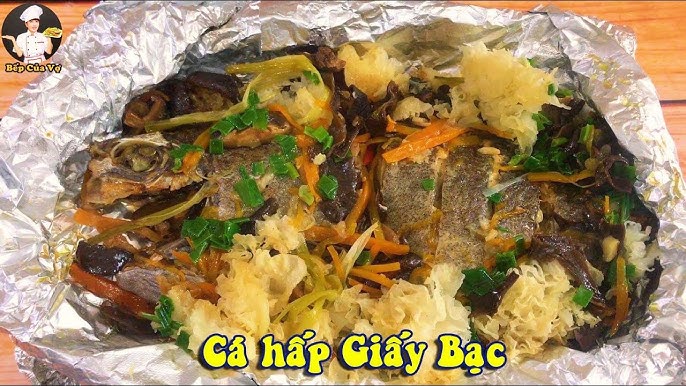

Image Content: A stunning, professional food photograph of a whole roasted branzino just being opened from its foil packet. Steam is gently rising, and the glistening fish is surrounded by herbs and lemon slices inside the foil.Caption: Theen papillote technique: a perfect synthesis of even cooking and intense flavor infusion.ALT Text: A perfectly cooked whole fish in an opened aluminum foil packet, showcasing the benefits of cooking seafood in foil.

2. Technical Specifications: A Non-Negotiable Framework for Culinary Foil

Mandatory material and safety certifications

Name: Culinary Foil Specification Protocol (CFSP-01)Icon: 📋Content: Material Designation: Food-Grade Aluminum. The foil MUST be explicitly labeled "Food-Grade" or "Food-Safe." This certifies that the aluminum alloy (typically 1xxx, 3xxx, or 8xxx series) is manufactured to purity standards that are safe for direct contact with food.Thickness (Micron Gauge): The single most important performance metric.Standard Duty (~12-16 µm): Suitable for wrapping or covering only. Not recommended for pouch-making.Heavy Duty (18-20 µm): The minimum standard for creating foil packets. It offers good puncture resistance and holds its shape.Extra-Heavy Duty (≥22 µm): The professional standard. Required for grilling over high heat, cooking heavy items, or when a perfect, leak-proof seal is non-negotiable.

Chemical Reactivity: Avoid using foil with highly acidic ingredients (e.g., tomato sauce, pure lemon juice) for prolonged periods, as it can cause a minor metallic taste and slight pitting of the foil. A thin layer of oil or a piece of parchment paper can act as a barrier.

Performance testing protocols for culinary application

The Puncture Test: Take a sharp-boned fish collar or a shrimp with its head and tail intact. Wrap it tightly in the foil. The foil should not puncture under moderate pressure. This simulates its ability to handle real-world ingredients without tearing.The Crimp & Seal Test: Create a sealed pouch with a double-folded seam. Fill it with a small amount of water. Hold it upside down and shake moderately. A high-quality foil will maintain a watertight seal, which is critical for preventing leaks on the grill or in the oven.The High-Heat Grill Test: Place an empty, sealed pouch on a hot grill (220°C / 425°F) for 10 minutes. A superior heavy-duty foil will not become brittle or disintegrate. It should remain pliable enough to be opened without tearing into pieces. Sub-standard foils will become weak and flaky.

3. Mastering the Method: Core Culinary Techniques for Foil-Cooked Seafood

A comparative analysis of primary cooking techniques

Method A - Baking/Roasting (Oven): Process: Seafood is enclosed in a foil packet with aromatics and liquid, then baked in a preheated oven.Result: This is the most gentle and foolproof method. It produces incredibly moist, tender fish, steamed in its own juices and the infused flavors. It offers supreme control and consistency. Example:Baked Salmon in Foil with Dill and Lemon .

Method B - Grilling: Process: A tightly sealed foil packet is placed directly on the grill grates.Result: This method offers a higher, more intense heat. The result is similar to baking but with the added benefit of a subtle smoky flavor that can permeate the foil. It is essential to use extra-heavy-duty foil and to flip the packet for even cooking. Example:Grilled Shrimp Scampi Foil Packets .

Method C - Steaming (over coals or in-pot): Process: The packet is placed on a rack over smoldering coals or in a pan with simmering water, but not in direct contact with the primary heat source.Result: This is the most delicate method, resulting in a texture akin to traditional steaming. It's ideal for very fragile fish like sole or flounder and allows their subtle flavors to shine. Example:Foil-Steamed Cod with Ginger and Scallions .

The "en papillote" modular formula for creative assembly

The Aromatic Bed (Component 1): This is the foundation that elevates the seafood and prevents it from sticking.Examples: Thinly sliced onions, fennel, leeks, or a bed of hearty herbs like thyme and rosemary.

The Protein (Component 2): The star of the show.Examples: Salmon fillet, cod loin, shrimp, scallops, or a small whole fish like branzino.

The Flavor Accents (Component 3): These are the primary seasoning agents.Examples: Minced garlic, sliced chili, capers, olives, sun-dried tomatoes, grated ginger.

The Liquid & Fat (Component 4): This creates the steam and adds richness.Examples: A splash of white wine, verjuice, or stock. A pat of butter, a drizzle of olive oil, or coconut milk.

The Finishing Touch (Component 5): Fresh herbs or citrus added for bright, top-note flavors.Examples: Sliced lemon or lime, sprigs of fresh dill, parsley, or cilantro.

Image Content: A vibrant and organized "mise en place" shot. On a clean cooking surface, you see all the components for a seafood foil packet laid out: a glistening salmon fillet, sliced lemons, fresh dill, capers, and a small bowl of olive oil, all next to a sheet of foil.Caption: The art of assembly: each component plays a strategic role in the final flavor profile.ALT Text: The ingredients for a salmon and dill foil packet prepared for assembly, illustrating the culinary foil technique.

4. Advanced Gastronomy: The Art of Flavor Infusion and Texture Control

The evolution of flavor infusion within a sealed environment

Traditional Model: The original concept ofen papillote focused primarily on moisture retention. Flavorings were simple: lemon, butter, and parsley. The goal was to steam the fish gently.Integrated Model: The modern chef views the foil pouch as a pressurized flavor vessel. The technique has evolved to incorporate principles from global cuisines.Phase 1 - Umami Infusion: Chefs now add umami-rich ingredients like miso paste, soy sauce, or a small piece of kombu to the packet. The steam and heat unlock and distribute these savory notes, deeply seasoning the fish from the inside out.Phase 2 - Aromatic Smoking: For a grilled application, a small handful of pre-soaked wood chips can be placednext to (not on) the packet. The smoke is so fine it will gently permeate the foil over 15-20 minutes, adding a subtle smoky essence without the harshness of direct smoking.Phase 3 - Compound Butters: Instead of a simple pat of butter, chefs create compound butters (e.g., anchovy-caper butter, chili-lime butter) that melt and baste the fish continuously throughout the cooking process, creating an integrated sauce right in the packet.

Food safety and textural perfection: a symbiotic relationship

Central Theme: The Foil Packet as a Safety & Quality Nexus Branch 1: Pathogen Elimination Even Cooking: The conductive nature of foil ensures heat reaches the thickest part of the fish, eliminating cold spots and guaranteeing the protein reaches a safe internal temperature (145°F / 63°C).Cross-Contamination Barrier: In a barbecue setting, the foil completely shields the delicate seafood from grill grates that may have been used for raw chicken or beef, providing a critical food safety barrier.

Branch 2: Textural Control Prevents Albumin Seepage: By cooking gently and evenly, the foil method reduces the amount of white albumin that leaches out of fish like salmon, leading to a more appealing final appearance.Protecting Delicate Proteins: Fragile seafood like scallops or thinly filleted sole, which can easily fall apart on a grill, are kept perfectly intact within the protective confines of the foil. This preserves their integrity and presentation value.

5. Operational Excellence: Best Practices and Pitfall Avoidance in the Kitchen

The professional's debate: heavy-duty vs. standard foil

Argument A (The Cost-Saver): "Standard foil is cheaper. I can just use a double layer. It's good enough for covering a pan, so it should be fine for a fish packet in the oven."Argument B (The Culinary Professional): "That is a fundamentally flawed premise. The structural integrity is not the same. A double layer of thin foil can still puncture easily from a fish bone or a sharp shrimp shell. More importantly, it doesn't hold a crisp, tight seam. A weak seam will leak precious liquid—the flavor base—into the oven or onto the grill, which then burns. The minimal cost saving is instantly negated by a single ruined dish, inconsistent results, and a mess to clean up. For a technique that relies entirely on a perfect seal, using anything less than extra-heavy-duty foil is an unacceptable operational risk."Conclusion: The professional always chooses the correct tool for the job. In high-stakes cooking, extra-heavy-duty foil is not a luxury; it is a necessity.

The masterclass protocol: a step-by-step execution framework

Preparation is Key: Cut a piece of foil approximately three times the size of the seafood portion. Place it shiny-side down (the dull side is slightly more non-stick).Build Your Base: Place your aromatic bed slightly off-center on the foil. This creates a raft for the fish to sit on.Season the Protein: Season the seafood itself generously with salt and pepper before placing it on the aromatic bed. Do not rely solely on the other ingredients for seasoning.Assemble and Seal: Add your remaining components (flavor accents, liquid, finishing touches). Bring the long sides of the foil together above the food. Fold them over twice, creating a tight, flat 1cm seam. Then, take each of the two ends and fold them over twice, crimping tightly to create a completely sealed, semi-circular packet. Ensure you leave some air/headspace inside the packet for steam to circulate.Cook with Precision: Place the packet on a baking sheet (as a precaution) or directly on the grill. Cook for the appropriate time based on the seafood's thickness (a general rule is 10-12 minutes per inch of thickness). The packet should be fully puffed up when done.Rest and Serve: Allow the packet to rest for 1-2 minutes off the heat. Present the entire packet to the guest or cut it open tableside for a dramatic release of aromatic steam.

Image Content: The final, dramatic presentation. A chef's hands, using a knife and fork, are elegantly cutting open a puffed-up, golden-brown foil packet at a dining table. Aromatic steam is visibly escaping, hinting at the delicious meal inside.Caption: The final reveal: a moment of culinary theater that engages all the senses.ALT Text: A chef presenting and opening a perfectly cooked seafood foil packet for serving.

(Conclusion Title) Aluminum Foil: A Strategic Asset for Culinary Precision and Excellence

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]