ELEVATING KITCHEN EFFICIENCY WITH SMALL FORMAT ALUMINUM FOIL

PRECISION WRAPPING SOLUTIONS: ELEVATING KITCHEN EFFICIENCY WITH SMALL FORMAT ALUMINUM FOIL

(Introduction Title) The Micro-Role with Macro-Impact: Re-evaluating Kitchen Essentials

In the grand orchestration of a professional kitchen or a high-volume catering operation, equipment like ovens and refrigerators often monopolize the discussion on capital expenditure. However, the consumables stream—specifically the localized use of aluminum foil—plays a silent yet critical role in daily throughput, food safety compliance, and ultimately, the profit and loss statement. While jumbo industrial rolls have their place in centralized processing, the strategic deployment of

1. DECENTRALIZED UTILITY: THE AGILITY OF COMPACT FOIL FORMATS IN COMMERCIAL OPERATIONS

The centralization of supplies often creates bottlenecks. In a high-pressure line cook environment, seconds saved translate to table turnover. We examine why "Right-Sizing" the packaging material is a logistical necessity.

Ergonomics and Station Efficiency: The "Zero-Step" Workflow

Cross-Contamination Control via Single-Station Deployment

The Blue Zone (Seafood): One dispenser exclusively for the fish station.The Red Zone (Meat): Distinct rolls for the grill.The Green Zone (Veg/Prep): Separate supply for salads and ready-to-eat items.The Outcome: Pathogen transfer via packaging material was eliminated. The compact nature of small rolls allows them to be color-coded or labeled and kept physically separate, adhering to the strictest HACCP (Hazard Analysis Critical Control Point) protocols. This level of hygiene granularity is impossible with a single central bulk roll.

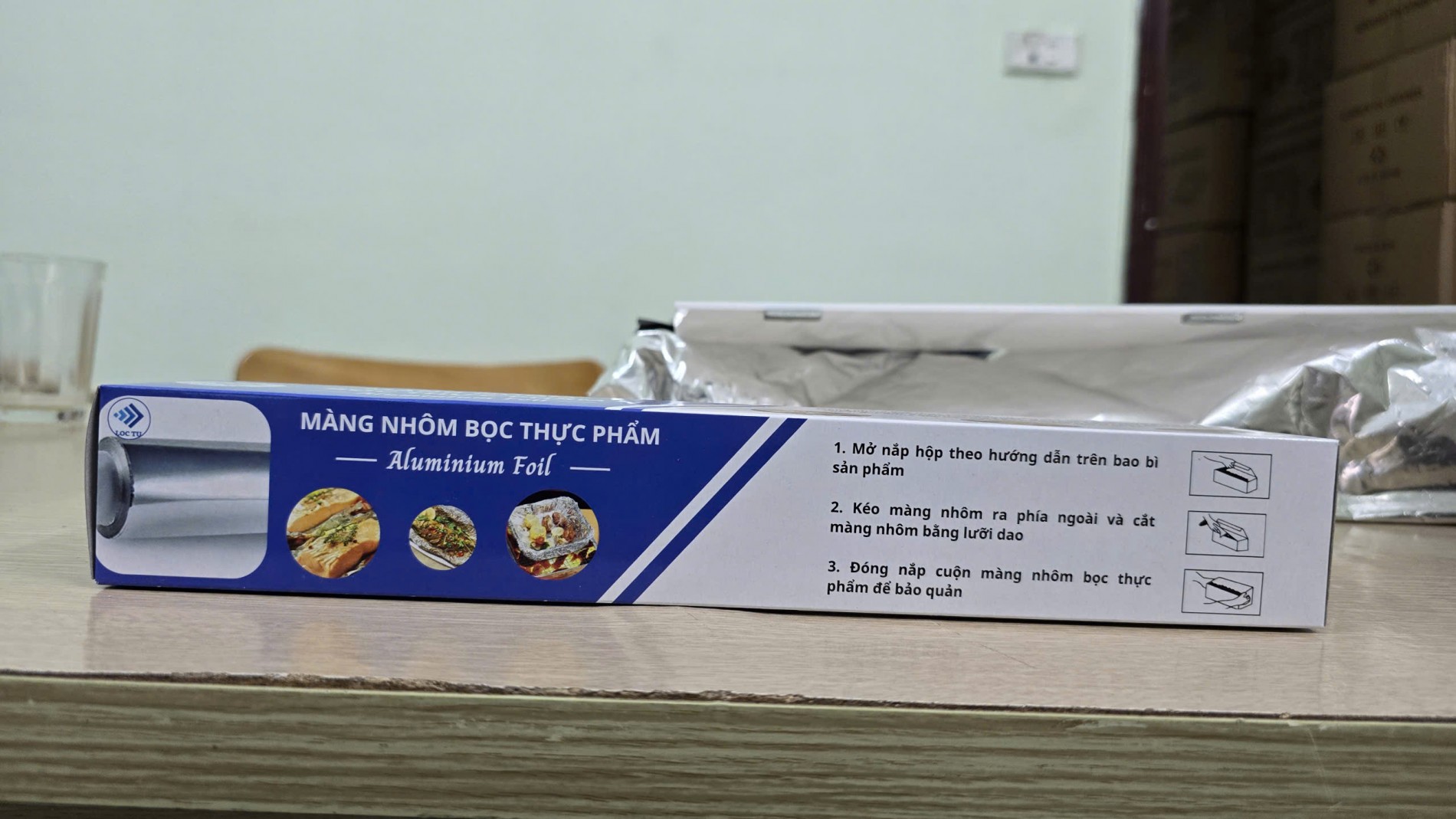

Image Content: A close-up shot of a stainless steel commercial kitchen line. A clearly labeled small box of aluminum foil with a serrated cutter is mounted securely within arm's reach of a chef plating a dish.Caption: Decentralized foil stations minimize movement and maximize hygiene control in professional environments.Alt Text: Chef using a convenient small aluminum foil roll at a commercial kitchen station for food safety.

2. THE METALLURGICAL STANDARD: AUDITING ALLOY PURITY AND TENSILE STRENGTH

Decoding the Micron Gauge: Balancing Malleability and Resistance

Below 12 µm: Too fragile for commercial speed. Tears easily when pulling fast from the box, leading to material waste and frustration.16-20 µm (Recommended): The optimal balance. It offers sufficient "Deadfold" characteristics (the ability to stay folded/wrapped without springing back) while resisting punctures from bone shards or heavy plating.Testing: When sourcing small rolls wholesale, demand a micrometer test. A variance of ±10% is unacceptable for high-precision culinary work. The structural integrity must support the weight of the food it wraps without bottoming out.

Chemical Safety Profiles: The Alloy 8011 vs. 3003 Debate

Common Grade: 8011 Alloy. This is the industry standard forfoodservice wrapping solutions because it is refined to be pinhole-free and fully annealed (soft temper), making it perfectly pliable for wrapping intricate shapes (like leftovers or odd-sized vegetables).The Manganese Factor (3003): Sometimes used for rigid containers, but for flexible rolls, purity is key.The Standard: Procurement must verify that the manufacturing process uses sterile rolling oils and that the final annealing removes all microbiological contaminants. Certifications like FDA or ISO 22000 are not optional badges; they are mandatory passports for the product to enter a professional kitchen.

3. THERMAL DYNAMICS & PRESENTATION: MULTI-FACETED APPLICATIONS IN PROFESSIONAL CULINARY ARTS

Thermodynamics in Action: En Papillote and Resting Membranes

Brand Aesthetics: The Visuals of Take-Out and Catering

Texture: A thick, commercial-grade small roll crumples aesthetically, looking intentional and secure rather than messy and cheap like thin supermarket foil.Visual Trust: Using bright, unblemished,sustainable food packaging (aluminum is infinitely recyclable) signals to the customer that the restaurant invests in quality.Customization: Small rolls are ideal for wrapping artisanal sandwiches or burritos where the foil itself acts as the plate. The rigidity of a 16-18 micron foil provides structure, preventing the food from getting crushed during transit.

Image Content: A beautifully captured overhead shot of a fish fillet cooked "en papillote" in aluminum foil, just opened to release steam, garnished with herbs.Caption: High-integrity foil creates perfect steam chambers, locking in flavor and moisture.Alt Text: Culinary application of aluminum foil cooking en papillote steam packet.

4. FINANCIAL FORENSICS: ASSESSING THE VALUE PROPOSITION OF STATION-BASED ROLLS

Waste Reduction Analysis: The Hidden Cost of the "Bad Cut"

The Calculation: If a kitchen saves just 10% of material usage by enabling precise, clean cuts tailored to the specific food item size, the perceived premium of the small roll is neutralized.Usability: Smaller widths (e.g., 30cm) are often perfect for plating and covering bowls, whereas a standard 45cm industrial roll creates massive overhang waste for smaller tasks.

Inventory Fluidity and Cash Flow Management

Storage Footprint: Small rolls stack easily on shelves or fit in drawers, requiring less dedicated floor space than bulk pallets.Cash Flow: Lower Minimum Order Quantity (MOQ) and unit price allow for more frequent, smaller orders. This keeps cash flow fluid compared to locking up capital in months' worth of jumbo roll stock.Scalability: Perfect for pop-up events, outdoor catering, or satellite kitchens where transporting heavy industrial equipment is unfeasible. Thecatering foil dispenser boxes are portable and self-contained.

5. PARTNERSHIP ARCHITECTURE: ESTABLISHING A SUPPLY CHAIN FOR PREMIUM CONSUMABLES

The Vetting Matrix: Beyond the Price Tag

Core Tolerance: Does the supplier guarantee the exact length (e.g., full 100m, not 95m)? Short-rolling is a common industry malpractice.Box durability: The carton itself must be robust. If the dispenser box collapses in a humid kitchen, the roll becomes unusable.Certifications: Immediate availability of COA (Certificate of Analysis) and migration testing reports forfood grade alloy 8011 .

The Loc Tu Manufacturing Commitment

Image Content: Inside the Loc Tu manufacturing facility. A clean-room environment showing high-speed automated machines rolling and boxing aluminum foil with precision.Caption: Advanced manufacturing guarantees sterile, consistent, and precisely measured foil products.Alt Text: Manufacturing process of high-quality small aluminum foil rolls at Loc Tu factory.

(Conclusion Title) THE FINAL WRAP: INVESTMENT IN AGILITY IS INVESTMENT IN GROWTH

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]