FOODSERVICE ALUMINUM FOIL: THE ULTIMATE GUIDE TO KITCHEN EFFICIENCY

FOODSERVICE ALUMINUM FOIL: THE ULTIMATE GUIDE TO KITCHEN EFFICIENCY & FOOD SAFETY

(Introduction Title) Beyond a Simple Wrap: Foil as a High-Performance Kitchen Asset

TABLE OF CONTENTS

Foundational Principles: The Strategic Role of Professional-Grade Aluminum Foil Technical Deconstruction: Critical Quality Metrics for Foodservice Aluminum Foil Economic Analysis: The True ROI of Investing in Premium Aluminum Foil Application Mastery: Integrating Foil into Advanced Culinary Workflows Procurement & Protocol: Best Practices for Sourcing and Using Aluminum Foil

1. Foundational Principles: The Strategic Role of Professional-Grade Aluminum Foil

Defining the strategic function of professional-grade foil

The core advantages of standardizing on foodservice foil

Strength - Unmatched Versatility: Professional foil is a multi-role asset. It functions as a wrapping material for preservation, a cooking vessel (en papillote), a heat shield for roasting, a non-stick liner for baking sheets, and even a makeshift tool for cleaning grills. This versatility is unmatched by other single-use materials.Strength - Superior Thermal Conductivity: Aluminum is an excellent conductor of heat. This property ensures even cooking and browning when used as a cover or lining and rapid chilling when used to wrap hot items for refrigeration, moving food quickly through the temperature "danger zone" and enhancing food safety.Opportunity - Enhanced Operational Efficiency: Heavy-duty and extra-heavy-duty grades reduce labor waste. Staff spend less time re-wrapping torn sheets, cleaning baked-on food from pans, or dealing with product failures. A well-placed foil dispenser can significantly speed up the prep and breakdown workflow.Opportunity - Culinary Innovation: The reliability of professional-grade foil empowers chefs. It enables consistent execution of advanced techniques like confit, steam-baking in pouches, or creating custom molds. This reliability allows for menu expansion and the delivery of higher-quality dishes.

2. Technical Deconstruction: Critical Quality Metrics for Foodservice Aluminum Foil

Mandatory specifications for procurement

Thickness (Gauge/Micron): This is the single most important metric. It is measured in Mils (1/1000th of an inch) or Microns (µm).Standard Duty (≈16 µm / 0.6 Mil): General purpose wrapping, short-term storage, covering containers.Heavy Duty (≈20 µm / 0.8 Mil): Ideal for pan lining, covering heavy items, moderate heat applications, and freezer storage. This is the workhorse of most kitchens.Extra-Heavy Duty (≥24 µm / 0.95 Mil): Required for high-heat cooking (grilling), wrapping bones or sharp items, and demanding transport applications.

Alloy & Purity: The foil must be made from a certified food-grade aluminum alloy (e.g., 1235 or 8011 series). The supplier must provide documentation confirming it is free from contaminants and complies with FDA or equivalent food contact safety standards.Tensile Strength & Puncture Resistance: While harder to quantify without lab equipment, these properties are a direct result of thickness and alloy quality. A supplier should be able to provide data on the foil's ability to resist tearing and puncturing, which is critical for preventing food spoilage and contamination.

An in-house protocol for performance testing

Step 1: The Puncture Test: Take a single sheet of foil. Place it over a hotel pan and stretch it taut. Attempt to puncture it with the corner of a solid, cold block of butter or a similar blunt kitchen object. Note the amount of pressure required. High-quality, heavy-duty foil will show significant resistance.Step 2: The Heat Brittleness Test: Line a sheet pan with the foil and place it in an oven at 220°C / 425°F for 15 minutes. After it cools, crumple it. Low-quality foils can become brittle and crack easily after high heat exposure.Step 3: The Seal & Wrap Test: Use the foil to tightly wrap an irregularly shaped item, like a head of broccoli or a trussed chicken. Assess how well the foil "dead-folds"—its ability to hold its shape and maintain a tight seal without springing back. This is crucial for proper food preservation.

3. Economic Analysis: The True ROI of Investing in Premium Aluminum Foil

Calculating the Total Cost of Ownership (TCO)

Branch 1: Direct Costs (The Obvious) Cost per roll / cost per meter. Shipping and handling fees. Dispenser box costs and durability.

Branch 2: Indirect Costs of POOR Quality (The Hidden Killers) Food Waste: The direct financial loss from food that spoils due to poor seals, freezer burn from punctures, or dries out from tearing under heat.Labor Inefficiency: Quantifiable time wasted by staff re-wrapping items, double-wrapping to compensate for low strength, and scrubbing pans that weren't adequately protected by a torn liner. (Calculate: 1 minute wasted per hour x 10 staff x 8-hour shift = 80 minutes of lost labor per day).Cross-Contamination Risk: The potential cost (financial and reputational) of a food safety incident caused by a compromised foil barrier between raw and cooked products in a refrigerator.Supply Waste: The cost of foil that is wasted when it tears improperly from a flimsy dispenser box.

How quality foil multiplies its own value

4. Application Mastery: Integrating Foil into Advanced Culinary Workflows

Foil as a workflow-optimization tool

Prep & Marinate: The vegetables are tossed with oil and seasonings directly on a heavy-duty foil-lined sheet pan.Cook: The pan goes directly into the oven. The foil promotes even roasting and radiant heat.Serve: The foil-lined pan can be placed directly onto a heated service line, with the foil acting as a clean, presentable, and disposable serving surface.Store & Cleanup: Leftovers can be quickly wrapped in the same foil. For cleanup, the foil is simply removed and discarded, leaving the pan nearly spotless. This workflow drastically reduces washing time and water consumption.

Creative assembly: foil-enabled culinary modules

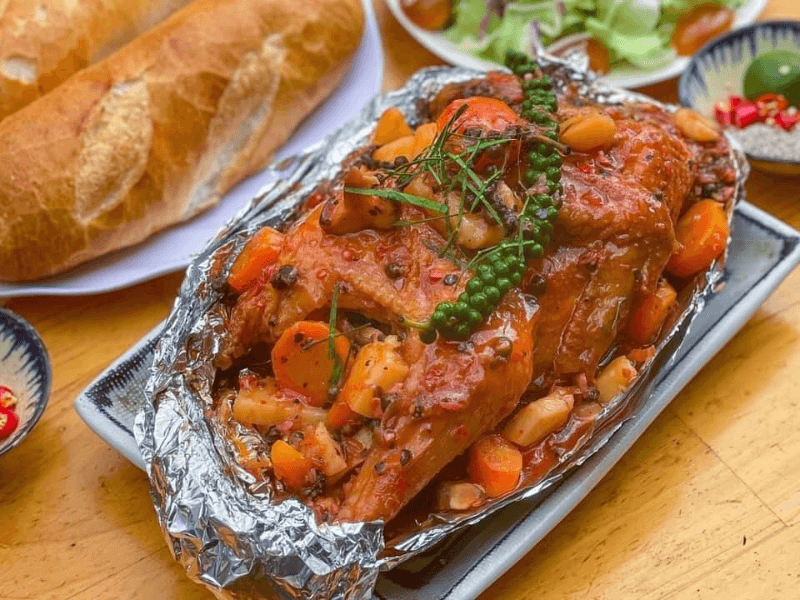

The "En Papillote" Steam-Infusion Module: Components: (1) A single, perfectly-portioned piece of fish or chicken + (2) Aromatic vegetables and herbs + (3) A splash of wine or stock + (4) A folded and sealed heavy-duty foil pouch.Application: These pouches can be pre-assembled during prep hours. Upon ordering, the pouch is baked in a high-temperature oven. It traps steam, infusing the protein with flavor and cooking it gently. It's then served directly in the opened pouch for a dramatic, aromatic presentation. This guarantees a moist, perfectly cooked product every single time.

The "Roasting Shield" Module: Components: (1) A whole chicken or turkey + (2) A molded piece of foil.Application: When roasting poultry, the breast meat often cooks faster than the thighs. By placing a "shield" of molded foil over the breast for the first half of the cooking time, you deflect direct heat, allowing the leg and thigh meat to catch up. The shield is removed for the final stage to allow for browning. This simple technique, reliant on foil, ensures a perfectly cooked, juicy bird from wing to thigh.

5. Procurement & Protocol: Best Practices for Sourcing and Using Aluminum Foil

Establishing a procurement checklist

In-house protocols for safety and efficiency

Dispenser Integrity: Start of shift, check that the cutting edge of the dispenser box is clean and secure. A faulty cutter creates waste and is a safety hazard. Ensure the roll is seated correctly to prevent snagging.Application Matching: Train staff to use the right tool for the job. Use Standard Duty for light covering, but mandate Heavy Duty for pan lining and freezer wrapping. Don't waste expensive Extra-Heavy Duty foil on a task a lighter grade can handle.Safety Bulletin - Acidic Foods: Post a clear notice: Do not use aluminum foil for long-term storage of highly acidic foods (e.g., tomato sauce, citrus marinades). The acid can cause the foil to leach a small amount of aluminum into the food, potentially causing a metallic taste and discoloration. Use plastic wrap or non-reactive containers for these items.The Shiny Side Myth: Officially bust the myth. For food contact, it makes no difference which side of the foil is used. The shiny and dull surfaces are simply a result of the manufacturing process. The only exception is non-stick foil, where the non-stick coating is applied to only one side (usually the dull side).

(Conclusion Title) Aluminum Foil: From a Kitchen Commodity to a Pillar of Operational Excellence

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]