HEAVY-DUTY VS. THIN-GAUGE ALUMINUM FOIL: A STRATEGIC OPERATIONAL ANALYSIS FOR COMMERCIAL KITCHENS

(Introduction Title) An Unassuming Roll: The Operational Leverage of Commercial Foil

In the meticulously calibrated environment of a commercial kitchen, every single component—from the heat of the range to the sharpness of the knives—is a variable that impacts the final product. Yet, amidst the high-tech equipment and premium ingredients, an often-overlooked asset holds significant operational leverage: the humble roll of aluminum foil. The procurement of this item is frequently relegated to a low-level purchasing decision, driven solely by cost-per-meter. This is a critical strategic error. The choice between heavy-duty and thin-gauge (or standard) foil is not merely a matter of thickness; it is a decision that sends ripples through every facet of the operation, influencing food quality, labor efficiency, food safety, and ultimately, the bottom line.

This document is not a buyer's catalog. It is a strategic operational analysis engineered for discerning culinary professionals, F&B proprietors, and supply chain managers. ✍️ From a veteran perspective, we will dismantle the conventional wisdom surrounding this kitchen staple. We will establish a rigorous framework for technical evaluation, conduct a true Total Cost of Ownership analysis that exposes the hidden liabilities of "cheaper" options, and create an application-specific blueprint for deployment. This analysis is built on a single premise: in a professional foodservice environment, the right aluminum foil is not a disposable commodity; it is a high-performance tool.

TABLE OF CONTENTS

Foundational Decisions: The Strategic Importance of Foil Selection

Technical Dissection: Differentiating Heavy-Duty and Thin-Gauge Foils

The Economic Equation: A Total Cost of Ownership (TCO) Analysis

Task-Specific Mastery: A Workflow Integration Blueprint

Strategic Procurement: Securing a Consistent and Quality Foil Supply

1. Foundational Decisions: The Strategic Importance of Foil Selection

The decision to standardize specific types of aluminum foil for specific tasks is a hallmark of a mature and efficient kitchen operation. It marks the transition from reactive problem-solving (e.g., "this foil keeps tearing") to proactive performance optimization. The correct selection establishes a baseline of quality and predictability that underpins culinary excellence.

Beyond the Wrap: Foil as a Critical Performance Variable

The Case: "The Hearthside Bistro," a successful farm-to-table restaurant known for its roasted meats and vegetables.

The Problem (The "Before"): To reduce costs, the purchasing manager switched to a single, low-cost, thin-gauge aluminum foil for all applications. The consequences were immediate and cascading. The foil would frequently tear when covering hotel pans of prepped ingredients, leading to cross-contamination risks and dried-out food. During high-heat roasting of their signature leg of lamb, the thin foil would break down and fuse to the meat and the pan, increasing plating time and creating a grueling cleaning process for the dish staff. This "cost-saving" measure was actually increasing labor hours and food waste.

The Solution (The "After"): After a formal review, the Head Chef implemented a dual-foil system. Thin-gauge foil was designated for light-duty tasks like wrapping individual sandwiches for catering orders or covering cooled items. A premium, heavy-duty foil was mandated for all high-heat cooking, lining pans for roasting, and long-term freezer storage.

The Result: Food waste due to drying out and tearing was virtually eliminated. Roasting performance improved, creating a more consistent product. Pan cleanup time was reduced by over 30%, freeing up the dishwashing team for other critical tasks. The marginal increase in the cost of the heavy-duty foil was overwhelmingly offset by the significant savings in labor, food, and consistency, demonstrating that foil selection is a strategic performance decision, not a simple line-item expense.

The Ripple Effect: How Foil Choice Impacts the Entire Kitchen Ecosystem

This framework analyzes the strategic decision to invest in a quality-centric, dual-foil procurement system.

Strength - Culinary Consistency & Quality: Heavy-duty foil provides superior heat retention and distribution, preventing hot spots and ensuring even cooking. It protects delicate proteins and maintains moisture, directly enhancing the quality of the final dish—a core brand strength.

Weakness - Higher Initial Procurement Cost: Premium heavy-duty foodservice foil has a higher per-meter cost than thin-gauge alternatives. This can appear as a negative variance on a purchasing budget if not viewed through a Total Cost of Ownership lens.

Opportunity - Operational Efficiency & Labor Savings: The primary opportunity lies in a dramatic reduction in "micro-failures." Eliminating the need for double-wrapping, reducing time spent on cleanup from torn foil, and faster prep times directly translate to lower labor costs and higher throughput during peak service hours.

Threat - Supply Chain Complacency: Relying on a single supplier for a cheap, unspecified "foil" product creates a significant threat. A supplier could substitute an even lower-grade product without notice, leading to a sudden drop in performance and potential food safety incidents. A strategic approach requires vetting suppliers and specifying exact product metrics.

[IMAGE 1 DESCRIPTION]

Image Content: A dramatic split-screen image. The left side shows a frustrated chef looking at a roasting pan where a thin piece of aluminum foil has torn and shredded over a piece of roasting chicken. The right side shows a pristine, perfectly tented piece of heavy-duty foil being lifted off a beautifully roasted turkey, with steam rising.

Caption: The difference is clear: The right tool for the job prevents costly failures and ensures culinary excellence.

ALT Text: A comparison of thin-gauge aluminum foil failing versus heavy-duty foil performing flawlessly in a kitchen.

2. Technical Dissection: Differentiating Heavy-Duty and Thin-Gauge Foils

A strategic approach to procurement demands a granular understanding of the material science that differentiates commercial foil grades. To the untrained eye, they are similar; to a professional, their performance characteristics are worlds apart. This vetting process moves beyond brand names and focuses on verifiable technical specifications.

The Science of Substance: A Micron-Level Specification Analysis

Name: Commercial Foil Specification Matrix (FSM-01)

Icon: 🔬

Content:

Thickness (Micron Gauge): This is the single most critical metric.

Thin-Gauge / Standard Foil: Typically ranges from 10 to 15 microns (µm). Suitable for wrapping, covering, and separating, but with low puncture resistance.

Heavy-Duty Foil: Must be a minimum of 16 µm, with premium foodservice grades often ranging from 18 to 25 µm. This provides significant tensile strength and puncture resistance.

Tensile Strength (MPa): Measures the force required to pull the foil to its breaking point. A heavy-duty foil will have a significantly higher Megapascal (MPa) rating, making it resistant to tearing under stress, such as when tightly covering a full hotel pan.

Puncture Resistance: Critical for wrapping bone-in meats or covering pans with sharp-edged contents. Heavy-duty foil's extra thickness and stronger alloy composition provide superior resistance to being pierced.

Alloy Composition: Foodservice foil is typically made from specific aluminum alloys (e.g., 1235 or 8011 series). While subtle, the alloy affects properties like formability and dead-fold (its ability to hold a wrapped shape), which are crucial for professional use. Always require a Certificate of Analysis (COA) from your supplier verifying the food-grade status.

Heat Dynamics: How Foil Grade Dictates Thermal Performance

This analysis examines how the physical properties of foil directly influence its performance in a high-heat environment, such as a commercial convection oven set to 220°C (425°F).

Scenario: Roasting Root Vegetables in a Lined Sheet Pan

With Thin-Gauge Foil: The lower mass and thickness result in less effective heat distribution. The shiny surface reflects radiant heat, but the material is prone to creating hot spots where it directly contacts the pan. It can easily scorch where sugars from the vegetables caramelize and can weld itself to the pan, creating a difficult-to-clean bond. Its low strength means it's likely to be punctured by the corner of a spatula during service.

With Heavy-Duty Foil: The greater thickness and mass act as a more effective heat buffer and conductor, distributing the oven's heat more evenly across the surface of the pan. This promotes uniform roasting and browning. Its superior strength and heat tolerance mean it resists scorching and will not break down or fuse to the pan. When service is complete, the entire liner can be lifted out cleanly, taking the mess with it and radically reducing pan-scrubbing time. The heavy-duty foil acts not just as a liner but as a piece of performance cookware.

3. The Economic Equation: A Total Cost of Ownership (TCO) Analysis

Focusing on the per-roll price is a tactical mistake that leads to strategic failure. A professional procurement analysis must encompass the Total Cost of Ownership (TCO), a framework that accounts for all direct and indirect costs associated with a product's lifecycle in the kitchen.

Deconstructing the Hidden Liabilities of Sub-Optimal Foil

Central Theme: The True Cost of a "Cheap" Roll of Foil

Branch 1: Direct Costs

Purchase Price Per Roll/Meter.

Shipping & Handling Fees.

Branch 2: Indirect Costs (The Financial Leaks)

Food Waste: This is the largest hidden cost. Calculate the value of a prime rib roast ruined because thin foil tore and the meat dried out. Factor in the cost of prepped vegetables that spoil because of a poor seal.

Labor Inefficiency: Quantify the extra time staff spend double-wrapping items. Measure the added minutes a dishwasher spends scrubbing pans where thin foil has fused. These minutes, multiplied across a year, represent thousands of dollars in wasted labor.

Consumable Waste: Document the amount of "wasted foil" itself—the pieces that are torn off the roll and immediately discarded because they rip before they can be used. This often requires using two feet of foil for a one-foot job.

Brand & Morale Damage: While harder to quantify, this is a real cost. The frustration of staff using tools that constantly fail affects morale. The inconsistency in food quality, even if minor, subtly erodes brand reputation over time.

Calculating the Tangible ROI of Premium Heavy-Duty Foil

Let's model the economic impact for a medium-sized catering business over one month.

Assumptions:

They use 10 rolls of thin foil OR 7 rolls of heavy-duty foil (due to no need for double-wrapping).

Thin Foil Cost:

15/roll−>∗∗

150/month Direct Cost.**Heavy-Duty Foil Cost:

25/roll−>∗∗

175/month Direct Cost.**Initial Analysis: Heavy-duty appears to be a $25 monthly loss.

TCO Calculation:

Labor Savings: Heavy-duty foil saves the prep team an estimated 10 minutes per day (no double-wrapping/re-wrapping) and the dish team 15 minutes per day (easier cleanup).

25 minutes/day * 30 days = 750 minutes (12.5 hours) / month.

At a labor rate of

20/hour,thisequals∗∗

250 in Labor Savings.**

Food Waste Savings: The business documents an average of $5 per day in food lost due to drying out or spoilage from failed thin-foil wrapping.

5/day∗30days=∗∗

150 in Food Waste Savings.**

Monthly ROI Calculation:

Total Savings (Labor + Food Waste): $250 +

150=∗∗

400**Net Gain: $400 (Total Savings) -

25(IncrementalFoilCost)=∗∗

375 per month.**Return on Investment: ($375 Net Gain / $175 Heavy-Duty Foil Cost) * 100 = 214% ROI.

This quantitative analysis proves that investing in the higher-priced, higher-quality product generates a significant positive financial return, transforming an apparent expense into a profitable investment.

[IMAGE 3 DESCRIPTION]

Image Content: A clean, professional infographic with a balance scale. On the left side, a small box labeled "Price Per Roll" is easily outweighed by several larger, red-colored blocks on the right labeled "Food Waste," "Wasted Labor," and "Consumable Waste."

Caption: A Total Cost of Ownership analysis reveals that the initial price is only a small fraction of the true economic impact.

ALT Text: An infographic chart showing the total cost of ownership of cheap foil is higher than heavy-duty foil.

4. Task-Specific Mastery: A Workflow Integration Blueprint

Operational excellence is achieved when the right tool is used for the right task, every time. Creating a clear, standardized protocol for foil usage eliminates guesswork, reduces waste, and optimizes outcomes across the entire kitchen workflow.

The Thin-Gauge Foil Playbook: For Precision, Protection, and Low-Intensity Tasks

Protocol: Light-Duty Application Standard Operating Procedure (SOP-FOIL-LD)

This protocol designates thin-gauge foil exclusively for tasks where its properties of flexibility and cost-effectiveness are an advantage, and its weaknesses are irrelevant.

Step 1 - Interleaving: When storing pre-sliced cheeses, burger patties, or baked goods, a small sheet of thin foil is used between layers. This prevents sticking without adding unnecessary bulk or cost.

Step 2 - Covering (Cooled Items): Use to cover containers of cooled or cold food items in the walk-in refrigerator (e.g., cut vegetables, salads, sauces). The purpose is simply to act as a dust cover and light barrier, not a high-moisture or airtight seal.

Step 3 - Individual Wrapping: Ideal for wrapping individual cold items for to-go orders, such as sandwiches or burritos. Its excellent "dead-fold" characteristic allows it to be tightly molded to the shape of the food.

Prohibition: This SOP expressly prohibits the use of thin-gauge foil for lining cooking pans, covering hot-holding containers, or wrapping bone-in items.

The Heavy-Duty Foil Arsenal: For Heat, Punctures, and Preservation

System: High-Performance Application Modules (HPAM)

This system deploys heavy-duty foil as an essential component in advanced culinary techniques and high-stress situations.

The "Oven Armor" Module:

Components: (1) Heavy-duty foil sheet + (1) Sheet pan or roasting pan.

Application: Lining any pan destined for the oven. This creates a non-stick, disposable surface that withstands high heat, protects the pan, and facilitates rapid cleanup. Essential for roasting, baking, and broiling.

The "Puncture-Proof Shield" Module:

Components: (1) Heavy-duty foil sheet + (1) Bone-in cut of meat (e.g., ribs, lamb rack, t-bone steak).

Application: Tightly wrapping bone-in items for grilling, roasting, or freezing. The foil's high puncture resistance prevents sharp bones from tearing the wrap, which would compromise moisture levels and lead to freezer burn.

The "Bain-Marie Seal" Module:

Components: (1) Heavy-duty foil sheet + (1) Hotel pan for a steam table.

Application: Creating a tight, drum-like seal over a pan of hot food. The foil's strength prevents it from sagging into the food and its thickness provides superior insulation, trapping heat and moisture far more effectively than thin foil and maintaining food quality for longer service periods.

5. Strategic Procurement: Securing a Consistent and Quality Foil Supply

Sourcing commercial aluminum foil is not a simple transaction; it is the establishment of a supply chain for a mission-critical operational asset. The goal is to build a partnership with a supplier who can guarantee not just a product, but also consistency, quality, and reliability.

The Supplier Vetting Protocol: Moving Beyond Price-Only Decisions

Voice A (The Cost-Focused Buyer): "This online wholesaler has a roll of 'heavy-duty' foil that's 20% cheaper than our current supplier. The numbers are simple; it's a direct saving. We should switch immediately."

Voice B (The Strategic Sourcing Manager): "Hold on. Does their 'heavy-duty' label come with a guaranteed micron spec sheet? Can they provide a Certificate of Analysis proving its food-grade alloy and country of origin? What is their stock guarantee policy for a key account like us—will they have product for us during the busy holiday season? A 20% 'saving' is worthless if a single bad batch ruins a $5,000 catering event or if they are out-of-stock in December. A reliable supplier provides not just a product, but supply chain insurance. That value is worth more than the 20%."

Resolution: The strategic manager prevails. The decision is made to only engage with suppliers who can provide full technical documentation and transparent supply chain logistics, treating the partnership as a risk mitigation strategy.

A Framework for Building a Resilient Foil Supply Chain

Name: Mission-Critical Consumables Supply Chain Checklist

Use this checklist to build a robust and reliable supply partnership for your aluminum foil needs.

[✓] Demand Full Technical Specification Sheets: Do not accept vague terms like "heavy duty." Require precise data: minimum micron thickness, alloy type, and roll dimensions (width and true length).

[✓] Require Food Safety Certifications: Request and verify documentation proving the material is food-grade and manufactured in a facility that meets recognized safety standards (e.g., ISO, NSF).

[✓] Conduct In-House Sample Testing: Before placing a bulk order, obtain a sample roll. Test it in your most demanding applications. Does it tear? Does it stand up to the heat of your oven? Does it feel consistent with the spec sheet?

[✓] Establish Clear Logistics and Inventory Terms: Define your ordering cadence and delivery schedule. Negotiate terms for emergency orders and understand your supplier's inventory levels to ensure they can meet your peak demand.

[✓] Qualify a Secondary Supplier: Even in a strong partnership, disruptions can happen. Identify and qualify a secondary supplier who meets all the above criteria. This creates redundancy and protects your operation from unforeseen supply chain shocks.

[IMAGE 5 DESCRIPTION]

Image Content: A professional and clean warehouse setting. A warehouse manager with a clipboard is inspecting a neatly stacked pallet of large, high-quality, branded foodservice aluminum foil rolls. The image conveys professionalism, organization, and a reliable supply.

Caption: A reliable supply chain is built on a foundation of verifiable quality and transparent partnership.

ALT Text: A warehouse symbolizing a strong, strategic procurement and supply chain for commercial aluminum foil.

(Conclusion Title) A Strategic Wrap: The Competitive Advantage of Deliberate Foil Selection

This in-depth analysis has systematically established that the choice between heavy-duty and thin-gauge aluminum foil is a critical decision with profound operational and financial consequences. The evidence overwhelmingly refutes the notion that foil is a simple commodity where the lowest price prevails. It is, instead, a fundamental component of the culinary production process.

Investing in premium, application-specific foil delivers a demonstrable return through reduced food waste, enhanced labor efficiency, superior culinary outcomes, and fortified brand integrity. By shifting from a cost-centric purchasing mindset to a TCO-driven strategic sourcing framework, F&B businesses can convert a mundane expense line into a source of competitive advantage. The deliberate, data-backed decision to equip a professional kitchen with the right tools is a foundational element in the relentless pursuit of operational excellence. 🏆📈

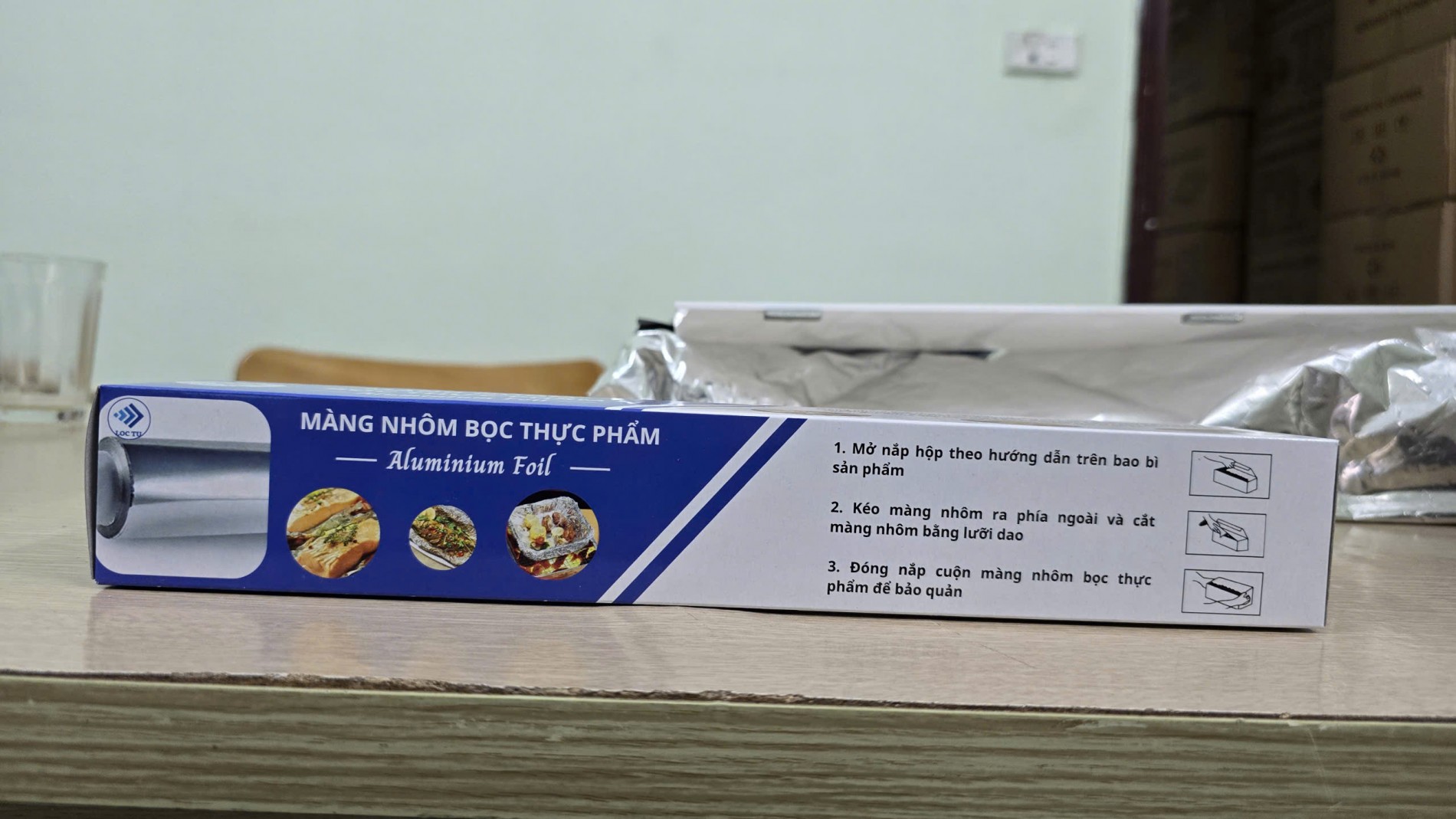

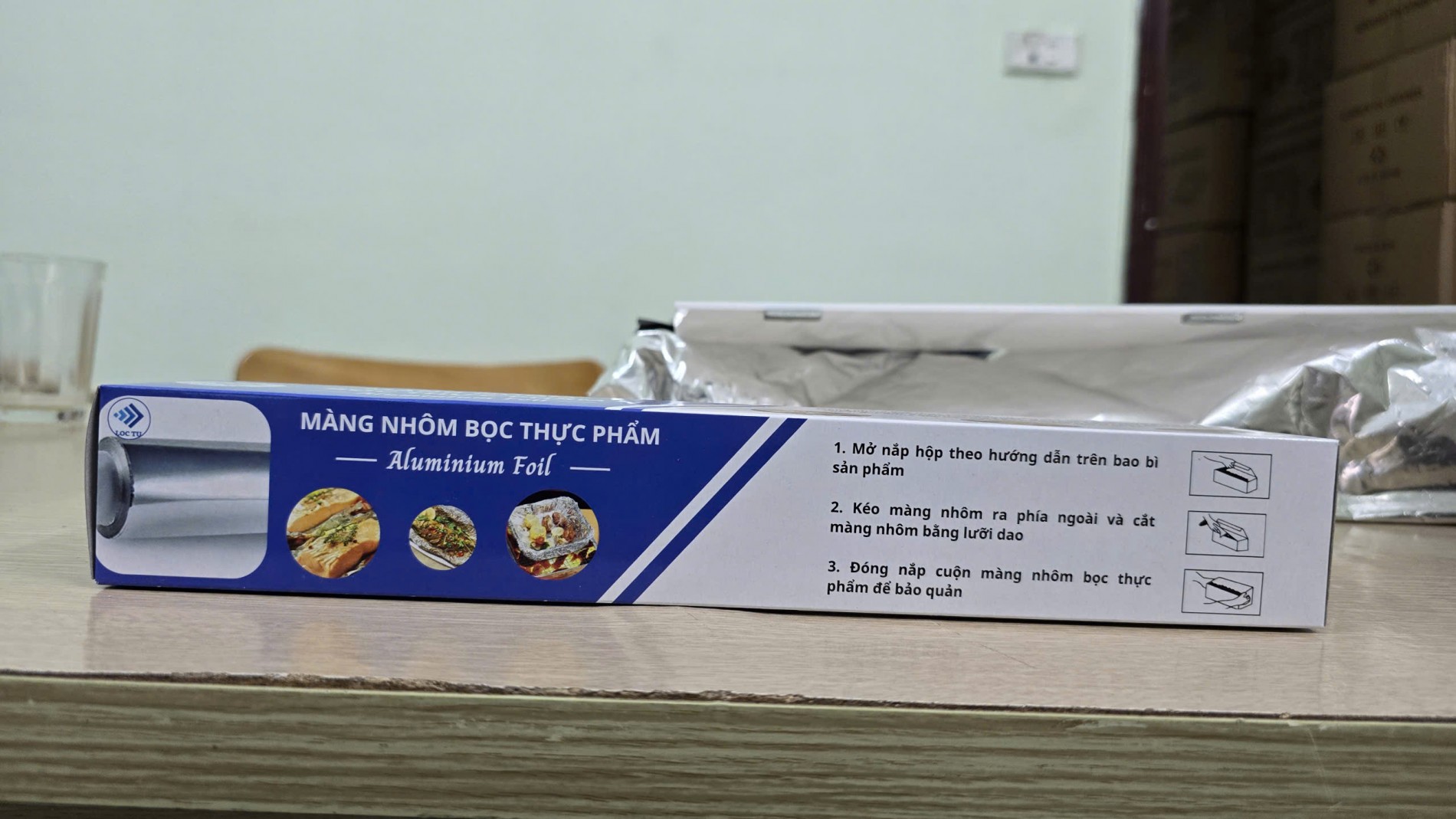

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

At the forefront of the food packaging industry, Loc Tu Manufacturing & Trading Co., Ltd. stands as a premier manufacturer and supplier of high-quality aluminum trays and foil rolls. We are dedicated to providing innovative, safe, and reliable packaging solutions tailored to the dynamic needs of the modern food landscape. Our foundation is b0uilt upon state-of-the-art manufacturing facilities, equipped with advanced production lines engineered for precision and efficiency. This technological edge allows Loc Tu to consistently deliver aluminum trays and foil rolls that not only meet but exceed rigorous international food safety standards.

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

Loc Tu Manufacturing & Trading Co., Ltd. is more than just a supplier; we are your strategic partner in delivering high-caliber aluminum food packaging solutions. Specializing in a comprehensive range of aluminum trays, versatile foil rolls, and convenient disposable food containers.

We serve a diverse clientele – from individual households and local food vendors to large-scale restaurants, catering companies, and prestigious hotel chains. Our unwavering dedication to safety, sustainability, innovation, and customer satisfaction makes us the trusted choice for businesses and consumers seeking reliable, high-performance packaging.

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀