INTERESTING FACTS ABOUT THE ORIGIN OF ALUMINUM FOIL

Introduction: The Origin of the Thin Foil Sheet – A "Witness" to Great Industrial Advancements

A Journey to Discover the "Roots" of Aluminum Foil Will Uncover:

Ancient "Predecessors": The Aspiration for Thin Metal Coatings. A Historical Turning Point: The Advent of Tin Foil – A "Sibling" of a Different Kind. The Aluminum Revolution: Who Invented Aluminum Foil and When? 3.1. Aluminum – A "Young" Metal with Limitless Potential. 3.2. Early Experiments and the Birth of Aluminum Foil. "Anatomy" of Foil: What is Aluminum Foil Made From and The Modern Aluminum Foil Manufacturing Process. 4.1. From Bauxite Ore to Pure Aluminum Ingots. 4.2. The Miraculous Rolling Process: Achieving "Unbelievable" Thinness. 4.3. Why Does Foil Have Two Different Sides (Shiny and Matte)? First Impressions: The Initial Applications of Aluminum Foil in Daily Life. The Development of Foil: From Luxury Item to Common Consumer Good. The Story of Foil: Interesting Anecdotes. Little-Known Interesting Facts About Aluminum Foil. Conclusion: Cherishing the Past, Towards a Sustainable Future for Aluminum Foil.

1. THE ORIGIN OF ALUMINUM FOIL - ANCIENT "PREDECESSORS": THE ASPIRATION FOR THIN METAL COATINGS

2. A HISTORICAL TURNING POINT: THE ADVENT OF TIN FOIL – A "SIBLING" OF A DIFFERENT KIND

Impact on Flavor: Tin could interact with certain foods, especially acidic ones, causing an unpleasant metallic taste.Less Ductile than Aluminum: It was harder to shape and tore more easily.Production Cost: Although not as expensive as gold or silver, mass-producing tin foil was still costly.

3. THE ALUMINUM REVOLUTION: WHO INVENTED ALUMINUM FOIL AND WHEN?

3.1. The Origin of Aluminum Foil: Aluminum – A "Young" Metal with Limitless Potential

3.2. Early Experiments and the Birth of Aluminum Foil

Early 1900s: Companies in Europe, particularly in Switzerland and France, began experimenting with rolling aluminum into thin sheets.1910: The Swiss company Tobler (famous for Toblerone chocolate) is credited as one of the first to use aluminum foil to wrap chocolate, helping to preserve flavor and prevent melting.1913: Life Savers, an American candy brand, started using aluminum foil to wrap their mints, keeping them fresh.

4. "ANATOMY" OF FOIL: THE ORIGIN OF ALUMINUM FOIL AND THE MODERN ALUMINUM FOIL MANUFACTURING PROCESS

4.1. From Bauxite Ore to Pure Aluminum Ingots

4.2. The Miraculous Rolling Process: Achieving "Unbelievable" Thinness

Hot Rolling: Large aluminum ingots are heated and passed through large rolling mills to progressively reduce their thickness into thinner sheets.Cold Rolling: The aluminum sheets are then passed through multiple pairs of rollers at room temperature. With each pass, the thickness of the aluminum decreases. This process is repeated many times.Double Rolling (For Very Thin Foil): To achieve the thinness of common household foil (typically only about 0.006 mm to 0.02 mm), two layers of foil are often rolled simultaneously. This helps prevent the foil from tearing during the ultra-thin rolling process.

4.3. Why Does Foil Have Two Different Sides (Shiny and Matte)?

When two layers of foil are rolled together, the side that comes into contact with the polished rolling mills becomes shiny. The side that is in contact with the other layer of foil (the inner surface of the "pair") will have a duller, matte finish because it doesn't directly touch the polished rollers.

5. FIRST IMPRESSIONS: THE INITIAL APPLICATIONS OF THE ORIGIN OF ALUMINUM FOIL IN MODERN LIFE

Wrapping candies, chocolates: Preserving flavor, preventing moisture, resisting melting. Wrapping tobacco: Maintaining moisture for tobacco. Making lids for milk bottles, yogurt cups: Creating a hygienic seal. Packaging for some pharmaceutical products.

6. THE DEVELOPMENT OF FOIL: FROM LUXURY ITEM TO COMMON CONSUMER GOOD

World War I and II: The demand for aluminum for military purposes surged, strongly boosting the development of the aluminum industry. After the wars, surplus production capacity was redirected to civilian products, including foil.1950s-1960s: Aluminum foil began to become common in households in America and Europe with the introduction of convenient household foil rolls.Growth of the Pre-packaged Food Industry: Foil played a crucial role in creating convenient packaging, such as aluminum food trays, milk cartons, and juice boxes.Today: Aluminum foil has become an indispensable item globally, with countless applications in kitchens, industry, and many other fields.

7. THE STORY OF FOIL: INTERESTING ANECDOTES

"Tin Foil Hat": Although modern foil is made from aluminum, the term "tin foil hat" still exists, referring to homemade hats made from foil that some people believe can block electromagnetic waves or mind control. Of course, this has no scientific basis, but it shows the presence of "tin/aluminum foil" in popular culture.Foil and Art: Some artists have used aluminum foil as a creative material to produce unique sculptures or installations.

8. LITTLE-KNOWN INTERESTING FACTS ABOUT THE ORIGIN OF ALUMINUM FOIL

Astonishing Thinness: Common household foil is typically only about 0.016 mm thick – thinner than a human hair!Infinite Recyclability: Aluminum can be recycled almost 100% without any loss of quality. Recycling aluminum consumes only about 5% of the energy needed to produce new aluminum from ore.The United States is one of the largest consumers of aluminum foil in the world. Besides aluminum, some other "metallic papers" exist, such as gold or silver-plated paper used in decoration, but they are not as common or food-safe as aluminum foil.

Quick Comparison Table: Tin Foil vs. Aluminum Foil (Modern)

| Feature | Tin Foil | Modern Aluminum Foil |

|---|---|---|

| Main Material | Tin (Sn) | Aluminum (Al) |

| Emergence | Late 19th, early 20th century | Early/Mid 20th century (popularized later) |

| Flavor Impact | May impart metallic taste to acidic food | Little to no flavor impact (if good quality) |

| Ductility | Less ductile | Highly ductile, easy to shape |

| Durability | Tears more easily | More durable (varies by thickness) |

| Cost | Relatively high (historically) | Inexpensive and widely available today |

| Current Status | Rarely used today, mostly obsolete | Extremely common in households and industries |

9. CONCLUSION: CHERISHING THE PAST, TOWARDS AN EXTREMELY SUSTAINABLE FUTURE FOR THE ORIGIN OF ALUMINUM FOIL

Ancient Times: Techniques for thinning gold, silver.Late 19th - Early 20th Century: Tin foil invented and applied.1886: Hall-Héroult process enables cheap aluminum production.Early 1910s: Aluminum foil begins commercial use for food wrapping.Mid-20th Century: Aluminum foil becomes a common household item.Present: An indispensable material with countless applications and high recycling potential.

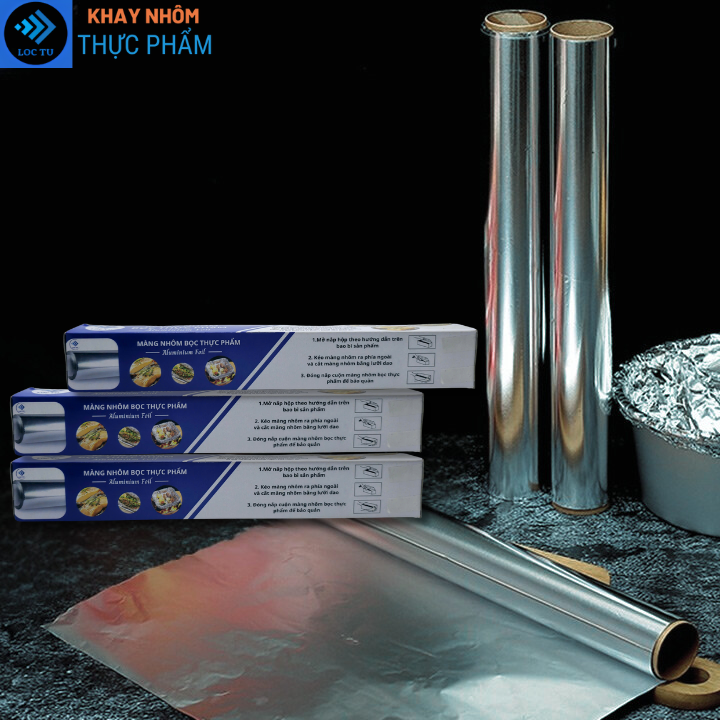

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why Choose Loc Tu:

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Website: ALUMINUMFOILVN

📌 HOTLINE/ZALO: +84.969.787.309

📌 Facebook: Khay nhom thuc pham

📌 Youtube: Khay nhom thuc pham Loc Tu

📌 Tik Tok: Khay nhom Loc Tu

📌 Shopee: Khay nhom thuc pham Loc Tu

📌 Telegram: Khay Nhom Thuc Pham Loc Tu

📌 Whatsapp: +84.969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays, foil, and food packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]