THE ALCHEMY OF SEAFOOD: MASTERING FLAVOR WITH ALUMINUM TECHNICS

THE ALCHEMY OF ENCLOSED SEAFOOD: MASTERING FLAVOR INFUSION WITH ALUMINUM TECHNICS

(Introduction Title) The Pursuit of Succulence: A Deviation from Direct Heat

1. Thermodynamic Efficiency: The Physics Behind the Aluminum Vessel

Analysis of heat circulation and retention mechanisms

Rapid Equilibrium: The container reaches the oven's ambient temperature almost instantly, initiating the cooking process without lag.The Steam Cycle: As the natural juices of the fish and added liquids reach 100°C (212°F), they vaporize. The impermeable nature of the aluminum traps this steam.Pressure Nuance: A slight pressure build-up forces the aromatic steamback into the protein structure, rather than letting it evaporate. This is the secret to "Impossible Moistness."

Material interaction: Ensuring safety and reactivity

Strength: Aluminum provides a total barrier to light, oxygen, and bacteria, preserving the freshness of the fish until the moment of consumption.Weakness (addressed): Raw aluminum can react with highly acidic ingredients (pure lemon juice, concentrated vinegar) causing a metallic taste or discoloration over long exposures.Optimization: For sophisticated recipes involving heavy acids, professional chefs utilizecoated aluminum containers or a parchment paper lining technique (composite layering) within the aluminum tray to harness the heat benefits while protecting flavor purity.

Image Content: A cross-section diagram (graphic) overlaying a photo of a fish inside a sealed aluminum container. Arrows show heat entering from the outside and steam circulating in loops on the inside.Caption: The Thermal Loop: How enclosed aluminum environments force moisture back into the fillet.ALT Text: Diagram showing heat circulation and steam retention inside an aluminum foil food container.

2. Ingredient Curation: Sourcing and Profiling for Enclosed Baking

The protein selection matrix

High Oil Content (Salmon, Black Cod, Chilean Sea Bass): These are the champions of this method. Their natural fats emulsify with the steam, creating a rich, velvety mouthfeel that is almost impossible to overcook in foil.Delicate/Lean White Fish (Tilapia, Snapper, Sole): These require shorter cook times and aggressive aromatics. The aluminum enclosure protects their fragile structure from disintegration, allowing for a flawless presentation upon opening.Shellfish (Shrimp, Clams, Mussels): Used as accent elements. They release briny liquors that form the base of the instant sauce created inside the container.

Aromatic synthesis and the "Flavor Base" concept

The Foundation: Sliced fennel, onions, or citrus wheels placed at the bottom of the aluminum tray.The Function: This layer lifts the fish off the bottom to prevent scorching (acting as a rack) and releases aromatic vapors upwards through the flesh.The Synergy: By the end of the cooking cycle, the juices from the fish drop down, mixing with the roasting vegetables to create a complexjus without any extra labor.

3. Structural Assembly: Engineering the Perfect Culinary Vessel

Layering logic for optimal heat penetration

Primitive Method: Throwing everything in a pile. Result: Uneven cooking, soggy vegetables, dry fish top.The Architectural Method: Dense Veg Base: Root vegetables or aromatics go first. They need the most heat conduction from the bottom of the aluminum tray.The Protein Center: The fish sits atop the base.The Lipid Cap: Butter pads, oil drizzle, or pestos go on top. As they melt, they baste the fish continuously (gravity-fed basting).The High-Note Finish: Delicate herbs (parsley, cilantro) should be addedafter cooking to prevent browning, unless buried under the sauce.

Sealing mechanics: The importance of the "Crimping" technique

The Air Pocket: Do not wrap tightly against the fish. Leave an air gap ("tenting") at the top. This space is essential for steam expansion.The Crimp: Fold the edges of the foil or the container rim tightly.The Check: Press gently on the packet. If air escapes easily, the steam will too. A tight seal builds the necessary pressure to drive flavors into the meat. For foil containers, ensuring the vertical wall is rigid (typical of high-quality wholesale products) helps secure the lid firmly.

Image Content: Macro photography shot focusing on the hands of a chef crimping the edges of an aluminum foil container lid. The metal texture is sharp, showing the secure seal.Caption: The Art of the Seal: Creating a miniature pressure cooker for maximum infusion.ALT Text: Chef sealing an aluminum food container to prepare for oven baking.

4. Thermal Execution: Managing Heat for Textural Perfection

Calibration of time and temperature curves

The High-Heat Blast (200°C/400°F - 10-15 Mins): Best for thinner fillets. It creates a vigorous steam environment immediately. Ideal for weeknight speed but risks unevenness in thick cuts.The Gentle Bake (160°C/325°F - 20-30 Mins): The connoisseur's choice for thick Salmon or Sea Bass cuts. It allows proteins to denature slowly, resulting in a texture often described as "buttery." The aluminum effectively moderates the harsh oven heat, creating a gentle radiant zone.

Sensory indicators of completion

The Novice: "I need to open it to check if it's done." ->Releases all the steam, ruins the timing. The Expert: "Trust the aromatics."The Smell Test: When the aroma suddenly shifts from "raw/marine" to "savory/cooked butter," the dish is 90% there.The Resistance Test: If using foil, gently poke the center (through the foil). If it feels firm yet springy (like the fleshy part of your palm), the proteins have set.Resting Phase: Just like steak, fish needs to rest for 3 minutessealed outside the oven. The residual heat in the aluminum completes the cooking process gently.

5. Sensory Calibration & The Standard of Material Excellence

The "Grand Reveal" presentation style

Theater at the Table: Do not unbox in the kitchen. Place the aluminum container or packet directly on the ceramic serving plate.Olfactory Impact: Instruct the guest (or family member) to pierce or open the seal at the table. The sudden release of aromatic steam—scented with dill, lemon, garlic, and sea salt—is a primary component of the flavor experience. This is known in neurology as "retronasal olfaction," priming the brain for the taste before the first bite.Visual Logic: The "rustic-industrial" look of shiny, clean aluminum contrasts beautifully with the vibrantly colored food, fitting perfectly into the modern casual-dining aesthetic.

Elevating results through professional sourcing (Loc Tu Integration)

Thickness Matters: Retail-grade foil is often 10-12 microns thin. It tears easily, causing juice leaks and dry fish. Professional-grade aluminum containers (standardized in Loc Tu’s catalog) often range from 16 to 25 microns.Rigidity & Safety: A rigid container supports the weight of heavier fish cuts and heavy sauce bases without buckling during transport from counter to oven to table.The Loc Tu Standard: Sourcing high-grade, food-certified aluminum containers isn't just for restaurants. It ensures that your "vessel" is chemically inert, thermally efficient, and structurally sound. To cook like a professional, one must use the specific gravity of tools that professionals utilize.

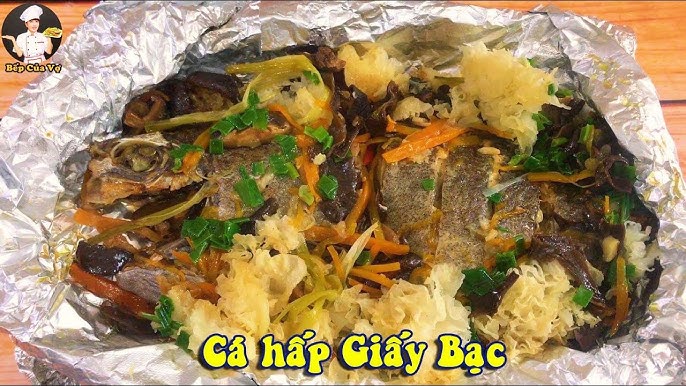

Image Content: A finished dish on a wooden dining table. The aluminum container lid is peeled back to reveal perfectly cooked, flaky fish with steam rising. A fork is lifting a piece of fish.Caption: The Grand Reveal: Unlocking the preserved aromas directly at the table.ALT Text: Delicious baked fish served directly in a premium Loc Tu aluminum foil container.

CONCLUSION (NO TITLE, JUST STRONG CLOSING)

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]