THE ENGINEERING OF PURITY: INSIDE THE ALUMINUM FOIL MANUFACTURING

THE ENGINEERING OF PURITY: INSIDE THE ALUMINUM FOIL MANUFACTURING LIFECYCLE

(Introduction Title) Technical Perfection in Microns

TABLE OF CONTENTS

Fundamental Metallurgy: Raw Material and Casting Alloy Composition and Purity Verification The Continuous Casting Phase

Precision Engineering: The Cold Rolling Mechanism Automatic Gauge Control (AGC) Dynamics Lubrication and Surface Quality Protocols

Thermal Dynamics: The Annealing Validation The Sterilization and Degreasing Mandate Temper Calibration: Hard vs. Dead Soft

Zero-Tolerance Metrics: The Integrity Audit Defect Detection and Pin-Hole Analysis Laboratory Tensile Testing Procedures

Final Conversion: Slitting and Commercial Distribution Customized Slitting for Specialized Applications The Loc Tu Supply Chain Integration

1. Fundamental Metallurgy: Raw Material and Casting

Alloy Composition and Purity Verification

Name: Alloy Integrity Sheet (AIS-Standard)Icon: 🧬Content: Primary Ingot Purity: The process must utilize primary aluminum ingots with a purity of at least 99.0% (often 99.5% for high-grade packaging). Recycled scraps with unknown origins are strictly prohibited in high-tier food-grade production.Key Alloys: 8011 Alloy: Enriched with Fe (Iron) and Si (Silicon) to enhance tensile strength and formability. The industry standard for household foil and containers.3003 Alloy: Includes Mn (Manganese) addition for approximately 20% higher strength, ideal for rigid container forming.

Audit Point: Every batch of raw ingots undergoesOptical Emission Spectrometry to confirm element distribution before melting.

The Continuous Casting Phase

Refining: Degassing units inject nitrogen or argon to remove hydrogen gas, which prevents porosity in the solid metal. Ceramic foam filters trap non-metallic impurities (slag/oxides).Twin-Roll Casting: Unlike traditional slab casting which requires huge energy to roll down, modern "Continuous Casting" processes pour molten aluminum directly between water-cooled rolls. The metal solidifies instantly into a sheet approximately6mm - 10mm thick .The Result: A giant master coil (Aluminum Jumbo Roll), often weighing several tons, ready for the reduction mills. This method ensures a refined grain structure, crucial for the extreme thinness required later.

Image Content: A dramatic industrial shot inside a foundry. Glowing molten aluminum is being poured into a continuous casting machine. Digital monitors in the foreground display temperature readings of 760°C.Caption: The Twin-Roll Casting process solidifies molten aluminum into master coils with refined grain structures.ALT Text: Molten aluminum processing in a foundry for aluminum foil manufacturing.

2. Precision Engineering: The Cold Rolling Mechanism

Automatic Gauge Control (AGC) Dynamics

Central Node: The Finishing MillBranch 1: X-Ray Sensors Continuously scan the foil moving at speeds up to 2000 meters per minute. Detect thickness deviations of even 0.1 micron.

Branch 2: Feedback Loop (The Brain) Sends instant data to the hydraulic rams. Adjusts the "Gap" between rollers in milliseconds.

Branch 3: Thermal Crown Control Sprays coolant on specific zones of the steel rollers. Controls the expansion of the roller itself to ensure the foil is perfectly flat, not wavy.

Lubrication and Surface Quality Protocols

The Technical Challenge: When rolling foil thinner than 50 microns, the material is so fragile it could break under tension. Furthermore, the work rolls themselves would touch, damaging the machine.The Engineering Solution: Doubling (Pack Rolling). Step 1: Two layers of foil are fed into the mill simultaneously.Step 2: A specialized lubricant (food-grade rolling oil) is sprayed between the layers.Step 3: They are rolled together.The Effect: The outside surfaces touch the polished steel rollers, becoming shiny (Bright Side ). The inside surfaces press against each other, creating a matte texture (Matte Side ).

Operational Outcome: This ingenious technique effectively doubles the mill's productivity while enabling the creation of ultra-thin foil down to 6 microns. The specific rolling oil formulation also ensures the foil surface remains pristine and stain-free during the high-pressure squeeze.

3. Thermal Dynamics: The Annealing Validation

The Sterilization and Degreasing Mandate

Historical Deficit: Decades ago, oil residues from the rolling process were manually cleaned or left on low-grade industrial foils. This posed a health risk and affected ink adhesion in printing.Modern Mandate: Today's annealing is not just about softening; it is the ultimateDegreasing Phase .The Process: Coils are placed in high-efficiency batch annealing furnaces.The Temperature: They are "soaked" at varying temperatures depending on requirements (approx 300°C - 450°C) for cycles lasting 12 to 24 hours.The Result: At these temperatures, the rolling oils vaporize completely. This yields a surface that is wettable (Grade A hygiene), sterile, and perfectly safe for direct food contact. B2B buyers must audit the supplier's annealing curves to guarantee this "burning off" is complete.

Temper Calibration: Hard vs. Dead Soft

State A: "H" Temper (Hard): Microstructure: Elongated grains, high dislocation density.Application: Push-through blister packs (pharma), rigid lids where bursting strength is needed.Properties: Rigid, springs back when folded, no degreasing cycle (oily surface unless treated).

State B: "O" Temper (Dead Soft): Microstructure: Recrystallized grains (Equiaxed).Application: Household foil, wrapping chocolate, molded containers.Properties: Perfectly pliable, "Dead-fold" characteristic (stays folded without glue), completely sterile and oil-free.

Image Content: Large industrial annealing furnaces. A forklift is placing a huge aluminum coil onto a rack to move it inside the glowing chamber.Caption: The thermal annealing cycle removes rolling lubricants and sets the mechanical temper.ALT Text: Industrial annealing furnaces used in aluminum foil production.

4. Zero-Tolerance Metrics: The Integrity Audit

Defect Detection and Pin-Hole Analysis

The Mechanism: A bright light source (lightbox) is placed behind the moving web of foil.The Metric: We look for"Pinholes" .7 micron foil: Maximum acceptable limit is typically less than 400 holes per square meter (Industry Std) vs. <100 holes (Loc Tu Premium Std).20+ micron foil: Must be essentially zero pinholes.

The Impact: Pinholes compromise the moisture barrier and oxygen barrier properties. For pharmaceutical or high-end food preservation, pinhole density is a critical KPI (Key Performance Indicator). Automated cameras map every defect; rolls exceeding the threshold are immediately flagged and scrapped.

Laboratory Tensile Testing Procedures

Name: Mechanical Stress Test (MST-04)Icon: ⚖️Content: Tensile Strength (UTS): Measures the force required to snap the foil.Standard: 60-100 MPa for "O" temper alloys.

Elongation (%): Measures how much the foil stretches before breaking.Criticality: Essential for forming containers. If elongation is too low, the foil will crack when pressed into a deep mold.

Burst Strength: Simulates the pressure of food or liquid inside a container.

5. Final Conversion: Slitting and Commercial Distribution

Customized Slitting for Specialized Applications

For Household Retail: The Jumbo roll is slit and rewound into thousands of small 3-meter to 75-meter rolls on paper cores, then boxed. The tension must be low to allow easy unrolling by the consumer.For Industrial Flexible Packaging: Slit into varying widths (e.g., 600mm, 800mm, 1200mm) depending on the printing press width. The winding must be extremely tight and the edge flushness (alignment) must be perfect (<1mm variance) to prevent telescope issues during high-speed lamination.The Lubrication Add-on: For container manufacturing feedstock, a specific pre-lubrication coating is often applied at this stage to assist in mold release later.

The Loc Tu Supply Chain Integration

Internal Monologue - The Buyer: "Why should I buy from Loc Tu instead of a generic trader?"The Consultant's Verdict: "A trader sees a box of product. A manufacturer like Loc Tu sees a metallurgical lineage.Loc Tu integrates the feedback from the Conversion Line back to theRolling Mill .If a client reports that the foil is 'too sticky' in their machine, we don't just replace it. We trace it back to the Annealing Temperature profile and adjust the curve for the next batch. We offer Just-In-Time (JIT) slitting capability, holding Jumbo stock and converting to specific widths only when you order, reducing your inventory costs and oxidation risks."

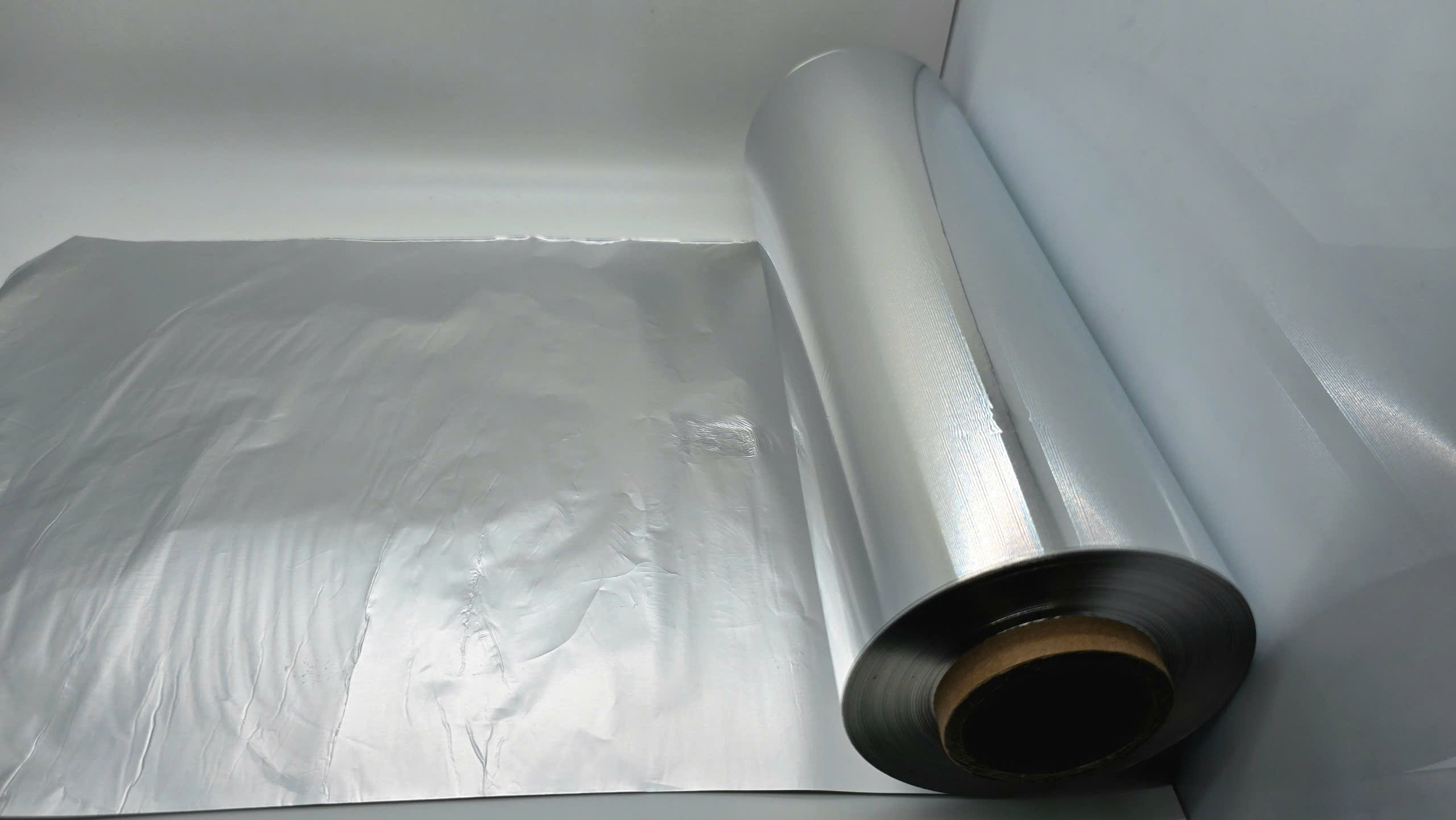

Image Content: Inside a clean, modern warehouse. Rows of neatly wrapped, large aluminum rolls are on pallets. In the background, a high-speed slitting machine is running. A Loc Tu staff member scans a barcode on a finished pallet.Caption: Vertical integration from slitting to delivery ensures traceability and rapid response to client specifications.ALT Text: Warehousing and slitting process of wholesale aluminum foil at Loc Tu factory.

(Conclusion Title) Precision as the Ultimate Barrier

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]