WHY DOES ALUMINUM FOIL TURN BLACK? A COMPREHENSIVE SCIENTIFIC REPORT

WHY DOES ALUMINUM FOIL TURN BLACK? A COMPREHENSIVE SCIENTIFIC REPORT ON THE CAUSES AND SAFETY IMPLICATIONS

(Introduction Title) A Scientific Explanation for a Common Kitchen Concern

TABLE OF CONTENTS

The Phenomenon: Investigating Why Does Aluminum Foil Turn Black Chemical Analysis: The Reactions Causing Foil Discoloration Safety Assessment: Are Black Spots on Foil Harmful? Prevention Protocol: How to Stop Aluminum Foil Turning Dark in Oven The Material Standard: The Role of Quality in Preventing Discoloration

1. The Phenomenon: Investigating Why Does Aluminum Foil Turn Black

A situational analysis of why does aluminum foil turn black

Case Study 1: Baking with Tomatoes. A chef bakes fish with a rich tomato and lemon sauce in a foil pouch. After cooking, he observes that the areas of the foil in direct contact with the sauce have turned a dull, dark grey color. The discoloration is widespread.Case Study 2: Storing Salt-Cured Meats. A home cook wraps leftover salt-cured ham tightly in aluminum foil and stores it in the refrigerator for several days. Upon unwrapping, she notices small, pitted, dark spots on the foil's surface.Case Study 3: Boiling with Hard Water. During a camping trip, a person uses a makeshift foil "pot" to boil well water that has a high mineral content. After boiling, the bottom of the foil has developed a chalky, dark residue.Common Factor: In all three cases, the aluminum foil was exposed to a chemically aggressive environment: high acidity, high salinity, or high alkalinity.

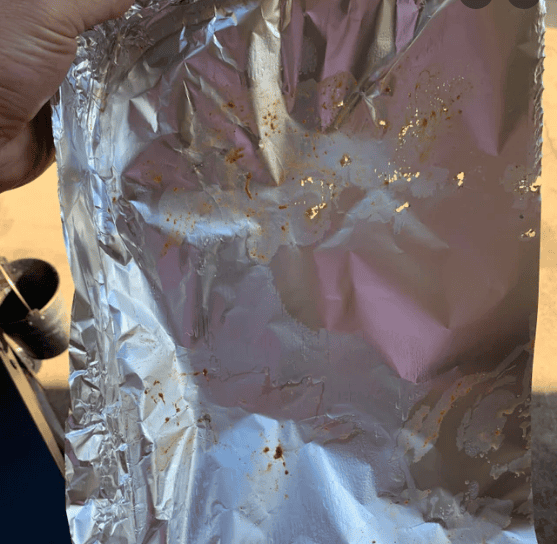

Defining the common types of discoloration

Branch 1: Widespread Dulling / Darkening Appearance: The foil loses its shine and turns a uniform dark grey or matte black.Common Cause: Exposure to highly acidic or alkaline substances.

Branch 2: Pitting and Dark Spots Appearance: Small, localized spots or pits that are dark in color.Common Cause: A galvanic corrosion reaction, typically caused by high concentrations of salt or contact with other metals.

Image Content: A professional, clean laboratory-style photo showing two pieces of used aluminum foil on a white background. One piece shows widespread dark grey dulling from an acidic food. The other shows small, dark pits from salt corrosion.Caption: Identifying the two common types of discoloration is key to understanding the cause.ALT Text: An image analyzing the different types of discoloration, a key part of understanding why does aluminum foil turn black.

2. Chemical Analysis: The Reactions Causing Foil Discoloration

The effect of acidic and alkaline environments

Neutral Foods (e.g., plain chicken, vegetables): These are like rain. They have little to no effect on the car's paint. The oxide layer remains stable.Highly Acidic/Alkaline Foods (e.g., tomatoes, lemon juice, certain mineral waters): These are like an aggressive chemical paint stripper. They can chemically dissolve the aluminum oxide layer. Once the protective "paint" is gone, the raw aluminum metal underneath is exposed and can react with the food, air, and moisture, forming complex aluminum compounds that appear as a dark, dull surface. This is the primarychemical reaction aluminum foil and food has.

The phenomenon of galvanic corrosion

Scenario: Why do salty foods sometimes create pits in the foil?Argument 1 (The Salt): "My high concentration of chloride ions is a very aggressive chemical agent. I can directly attack the oxide layer in very small, localized spots."Argument 2 (The Water/Moisture): "I act as the electrolyte. I create a medium that allows for a tiny electrochemical cell, or battery, to form on the surface of the foil."The Scientific Conclusion: This process is called galvanic corrosion or pitting. The combination of chloride ions from salt and moisture creates a mini-battery on the foil's surface. This rapidly corrodes the aluminum in a very small area, forming a pit. The byproducts of this corrosion are what you see as the dark spots. This explains theoxidation of aluminum foil in specific points.

3. Safety Assessment: Are Black Spots on Foil Harmful?

An analysis of is blackened aluminum foil safe to eat

Question: What are the black spots actually made of?Expert Answer: The dark residue is primarily composed of various non-toxic aluminum compounds (like aluminum salts or oxides) formed during the chemical reaction. It is not mold, and it is not a harmful organic substance.Question: Does this mean aluminum is leaching into the food?Expert Answer: Yes, a very small amount of aluminum does transfer to the food during this reaction.Question: So,is blackened aluminum foil safe to eat from?Expert Answer: According to major global health bodies, including the WHO and FDA, the amount of aluminum that might migrate to food, even in these extreme-use cases, is considered physiologically insignificant. The human body absorbs very little aluminum, and the amounts ingested from cookware are far below the established safety thresholds. While the appearance may be unappetizing, it is not considered a health risk.

Distinguishing discoloration from quality issues

The Myth: "If my foil turns black, it must be a cheap, low-quality product."The Truth: 🧐 This is not necessarily true. In fact, this chemical reaction will happen toany aluminum foil, regardless of its quality or brand, when exposed to sufficiently aggressive conditions.The Real Quality Issue: A low-quality,non-food grade aluminum foil poses a different risk. It may contain impurities of other heavy metals like lead. While these are unlikely to be the cause of the blackening, they are a separate health concern. This is why always choosing a certified food-grade foil, like that fromLoc Tu , is crucial.

Image Content: A clear infographic. It shows an image of a discolored foil with a label saying "Chemical Reaction (Not harmful)". Next to it is a symbol for lead (Pb) with a red cross, labeled "Heavy Metal Impurity (Harmful - Avoided by Food Grade)."Caption: Differentiating between a harmless chemical reaction and a potential material quality issue.ALT Text: An infographic providing a safety assessment and explaining if is blackened aluminum foil safe to eat.

4. Prevention Protocol: How to Stop Aluminum Foil Turning Dark in Oven

The principle of avoiding direct contact to stop aluminum foil turning dark in oven

The Problem: Lasagna contains a rich, acidic tomato sauce that can cause the foil pan to darken.The Solution: A Parchment Paper Liner. Before assembling the lasagna, a professional chef first lines the inside of the aluminum foil pan with a sheet of parchment paper.The Assembly: They then build the layers of pasta, sauce, and cheese on top of the parchment paper.The Result: The parchment paper acts as an inert, non-reactive barrier. The food gets all the benefits of the foil pan's even heat conduction, but the acidic sauce never touches the aluminum. The pan remains bright and shiny.

A checklist for the prevention of foil discoloration

[✅] Assess Your Ingredients: Is your dish very high in acid (tomatoes, lemon, vinegar) or salt (pickles, cured meats)?[✅] If YES, Create a Barrier: Use a liner of parchment paper or a natural liner like a cabbage or banana leaf between the food and the foil.[✅] Minimize Contact Time: Avoid long-term storage (many days) of highly acidic or salty leftovers directly in aluminum foil in the refrigerator. Transfer them to a glass or ceramic container instead.

[✅] Avoid Other Metals: Do not use metal utensils to serve salty or acidic food directly from a foil pan, as this can accelerate galvanic corrosion.

5. The Material Standard: The Role of Quality in Preventing Discoloration

The importance of a high-quality oxide layer

Branch 1: Raw Material Purity Effect: Afood grade aluminum product is made from high-purity alloy. This ensures that even if some minimal leaching occurs, only aluminum is transferred, not other harmful metals.

Branch 2: Manufacturing Process Effect: A controlled manufacturing process, including the final annealing stage, helps to form a thicker, more uniform, and more stable protective oxide layer.

Branch 3: The Result Effect: A better-formed oxide layer may offer slightly higher resistance to mild acids, providing an extra margin of safety and performance. This is why a brand like Loc Tu insists on a strict production process.

Why a quality product is the safest baseline

"Ultimately, the answer to 'why does aluminum foil turn black' is chemistry. But the answer to consumer peace of mind is quality assurance. By choosing a product from a reputable manufacturer like Loc Tu, which is certified food grade and produced under strict quality controls, the user establishes the safest possible baseline.

From there, applying correct usage techniques for acidic foods becomes a simple matter of best practice, not a source of health anxiety."

Image Content: A professional shot of a Loc Tu branded aluminum foil roll. The packaging clearly features prominent "Food Grade" and "ISO 9001" certification seals.Caption: Starting with a certified, high-quality product is the first and most important step to safety and peace of mind.ALT Text: The material standard: Loc Tu's certified quality is the safest baseline, helping to address why does aluminum foil turn black.

(Conclusion Title) Aluminum Foil Discoloration: A Solved Chemical Mystery

Loc Tu: Pioneering Excellence in Premium Aluminum Packaging Solutions

Why You Must Choose Loc Tu?

✅ Assured Quality & Safety: Crafted from premium, food-grade aluminum, free from harmful impurities, meeting international safety benchmarks.

🔥 Optimal Thermal Properties: Ensures even cooking and excellent heat retention, preserving food temperature and taste effectively.

💪 Durable & Convenient Design: Engineered to resist leaks and dents, providing reliable performance for baking, storage, and transport.

🔄 Versatile Solutions: Our extensive range caters to various applications – from baking and steaming to storing fresh food and takeaway meals.

🌱 Eco-Conscious Packaging: Made from 100% recyclable aluminum, supporting sustainability and reducing plastic waste.

🎯 Brand Enhancement: Optional custom printing available to personalize products and boost your brand visibility.

🚚 Reliable Supply & Delivery: Capable of handling large orders with dependable, on-schedule nationwide shipping.

Loc Tu – Trusted Manufacturer of Durable Aluminum Foil Containers and High-Quality, Food-Safe Aluminum Foil Rolls for Your Kitchen

Your Trusted Partner in Food Packaging 📞

📌 LOC TU MANUFACTURING & TRADING CO., LTD

📌 Our Vietnamese Website: Khaynhomthucpham.com

📌 HOTLINE/ZALO: 0969.787.309

📌 Facebook: Aluminum Foil Loc Tu

📌 Youtube: Aluminum Foil Loc Tu

📌 Tik Tok: Aluminum Foil Loc Tu

📌 Instagram: Aluminum Foil Loc Tu

📌 Shopee: Aluminum Foil Loc Tu

📌 Twitter/X: Aluminum Foil Loc Tu

📌 LinkedIn: Aluminum Foil Loc Tu

📌 Pinterest: Aluminum Foil Loc Tu

📌 Tumblr: Aluminum Foil Loc Tu

📌 Threads: Aluminum Foil Loc Tu

📌 Telegram: Aluminum Foil Loc Tu

📌 Whatsapp: 0969.787.309

📌 Branch 1 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District, Hanoi

📌 Branch 2 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City, Binh Duong Province

📞 Contact us today for expert consultation and the best pricing on premium aluminum trays and foil packaging solutions! 🚀

LOC TU PRODUCTION AND TRADING COMPANY LIMITED

Branch 1 (Binh Duong): No. 68, DX 051 Street, Group 17, Quarter 4, Phu My Ward, Thu Dau Mot City.

Branch 2 (Hanoi): No. 1 Pham Tu, Beasky Building, Dai Kim Ward, Hoang Mai District.

Hotline/Zalo: +84.969787309

Website: Khaynhomthucpham.com

Email: [email protected]